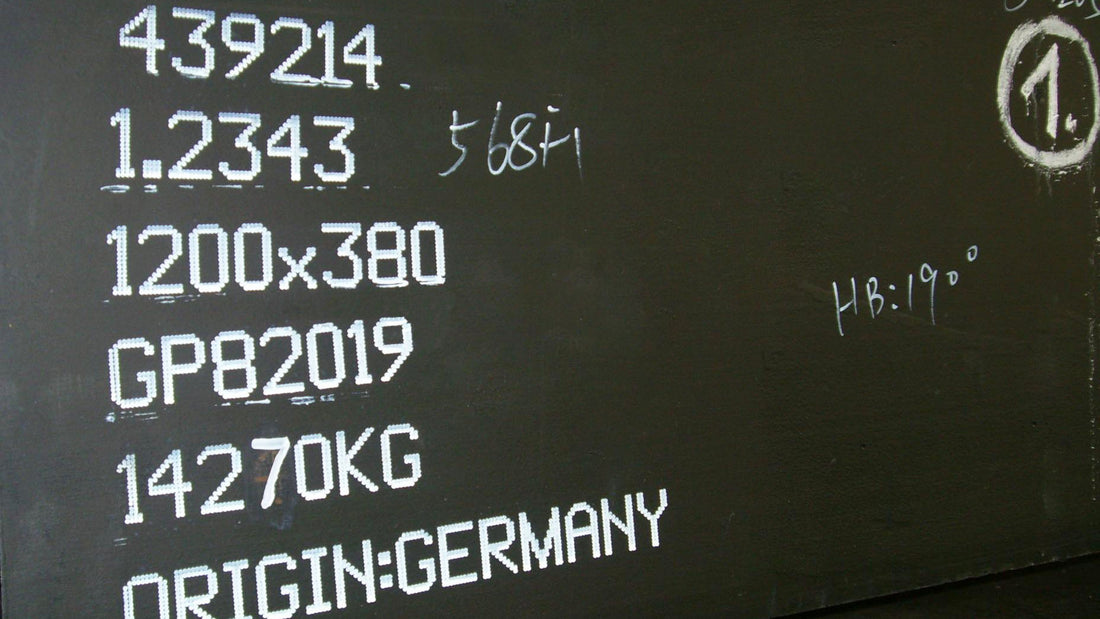

Steel DIN 1.2343 (Material X37CrMoV5-1)

DIN 1.2343 steel is a hot work tool steel, the equivalent material in the USA is H11 steel, which has excellent machinability and polishability, good toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance .

The application of 1.2343 ESU steel (X37CrMoV5-1) is in die casting molds for processing light metals, cylinders and pistons in cold chamber machines, metal extrusion tools, etc.

1.2343 Steel Properties

The tables below show properties of 1.2343 steel, such as chemical composition, physical and mechanical properties, etc.

Chemical composition

Based on cast analysis

| Chemical composition, % | |||||||||

| Standard | Steel Number (Name) | W | Yes | Mn | P, ≤ | S, ≤ | Cr | Mo | V |

| EN ISO 4957 | 1.2343 (X37CrMoV5-1) | 0.33-0.41 | 0.90-1.20 | 0.25-0.50 | 0.03 | 0.02 | 4.8-5.5 | 1.10-1.50 | 0.30-0.50 |

| DIN 17350 | 1.2343 (X38CrMoV5-1) | 0.36-0.42 | 0.80-1.20 | 0.30-0.50 | 0.03 | 0.03 | 4.8-5.5 | 1.10-1.40 | 0.25-0.50 |

Physical properties

| Physical properties | |

| Density, g/cm3 | 7.85 |

| Electrical resistivity, μΩ·m | 0.52 (20ºC) |

| Specific heat capacity, J/(kg·K) | 460 (20ºC) |

| Thermal conductivity, (W/m·K) | 15.0 (20°C) |

| Thermal conductivity, (W/m·K), annealed | 29.8 (20°C) |

| 30.0 (350°C) | |

| 33.4 (700°C) | |

| Thermal conductivity, (W/m·K), hardened and tempered | 26.8 (20°C) |

| 27.3 (350°C) | |

| 30.3 (700°C) | |

| Modulus of elasticity, GPa | 210 |

| Average coefficient of thermal expansion, (10 -6 /K) | 11.8 (20-100°C) |

| 12.4 (20-200°C) | |

| 12.6 (20-300°C) | |

| 12.7 (20-400°C) | |

| 12.8 (20-500°C) | |

| 12.9 (20-600°C) | |

| 12.9 (20-700°C) | |

Mechanical properties

Tensile strength DIN 1.2343: > 1400 MPa (<150 °C).

Hardness at different tempering temperatures.

| Quenching temperature (°C) | Hardness (HRC) |

| 50 | 53.7 |

| 100 | 53 |

| 200 | 52 |

| 300 | 52.5 |

| 400 | 54.5 |

| 450 | 56 |

| 500 | 56 |

| 550 | 52 |

| 600 | 46 |

| 650 | 39 |

| 700 | 31 |

Heat treatment

Critical temperatures (°C): 830 (Ac 1b ), 900 (Ac 1e ), 340 (M é )

Full annealing: 870°C-900°C (1600°F – 1650°F); Hardness: ≤229 HBW (annealed)

Material hardening 1.2343: Austenitizing temperature 1020±10 °C; Quenching agent: Oil; The corresponding tempering temperature and HRC hardness can be found above.

DIN EN 1.2343 Equivalent steel grades

The equivalent material of 1.2343 steel (1.2343 ESR) is listed in the following table, for example, ASTM standard, ISO standard, Chinese GB standard, Japanese JIS standard.

| Equivalent steel grades DIN 1.2343 | |||||||||

| European Union | USA | ISO | China | Japan | |||||

| Standard | Steel Name (Material Number) | Standard | Note (UNS) | Standard | Steel Name | Standard | Note | Standard | Note |

| EN ISO 4957 | X37CrMoV5-1 (1.2343) | ASTM A681 | H11 | ISO 4957 | X37CrMoV5-1 | GB/T 1299 | 4Cr5MoVSi | JIS G4404 | SKD6 |

Related materials: En24, En8 (BS970 080M40), DC01 (1.0330), Job 1.2343