Carbon steel is one of the most used materials in industry due to its versatility and efficient cost. This type of steel is an iron-carbon alloy that contains up to 2.0% carbon, as well as small amounts of impurity elements such as manganese, silicon, sulfur, phosphorus and oxygen. The carbon proportion is what mainly defines the mechanical characteristics of steel, dividing it into three main categories: low, medium and high carbon. Each of these categories is suitable for different applications due to their unique properties.

Classification of Carbon Steel

Carbon steel is classified based on carbon content, which directly affects its mechanical properties and applicability:

1. Low Carbon Steel

- Carbon Content : 0.04% to 0.29%

- Properties : This type of steel is known for its ductility and malleability. It has low strength and hardness but high plasticity, making it ideal for cold forming without cracking.

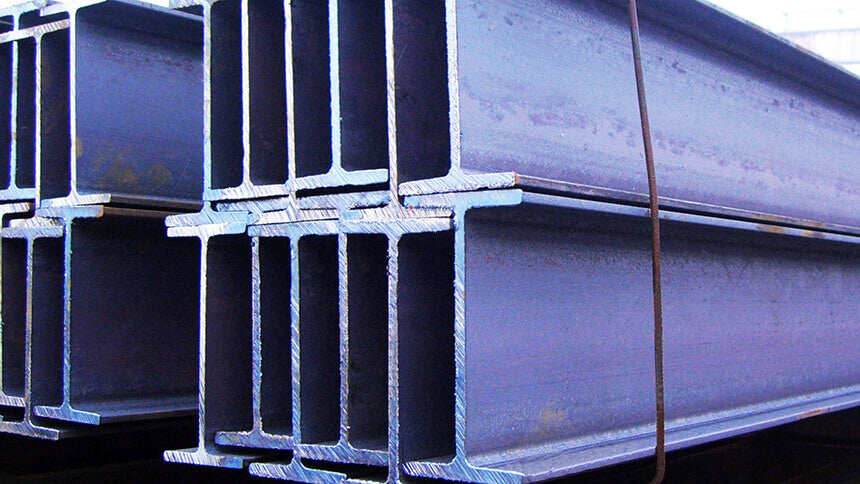

- Applications : Widely used in civil construction for metallic structures, automobile components, and in the manufacture of steel tubes and plates that do not require great resistance.

2. Medium Carbon Steel

- Carbon Content : 0.29% to 0.60%

- Properties : It offers a balance between ductility and resistance, being more resistant than low carbon steel, but still allowing a certain conformation.

- Applications : Ideal for machine and vehicle parts that require greater strength and toughness, such as axles, gears, and forged parts that can be subjected to heat treatments to improve their strength and hardness.

3. High Carbon Steel

- Carbon Content : 0.60% to 2.0%

- Properties : It is characterized by its high resistance and hardness, but with lower ductility, which makes it more susceptible to breakage when deformed.

- Applications : Commonly used in the manufacture of cutting tools, springs, and other components that require high resistance to wear and fatigue.

Comparison between Types of Carbon Steel

| Types of Steel | Carbon Content (C%) | Characteristics | Common Applications |

|---|---|---|---|

| Low carbon steel | 0.04 ≤ C ≤ 0.29 | Low strength, high ductility | Building structures, automotive components |

| Medium Carbon Steel | 0.29 < C < 0.60 | Balance between strength and ductility | Machine parts, gears |

| High carbon steel | 0.60 ≤ C < 2.0 | High strength, low ductility | Cutting tools, springs |

Thermal treatments

The performance of carbon steel can be improved through specific heat treatments, which alter its microstructure and properties:

- Austenitization : Heating the steel to a temperature that forms the austenitic phase, ideal for adjustments in hardness and resistance.

- Tempering : Rapid cooling to transform austenite into martensite, increasing hardness and resistance.

- Tempering : Subsequent heating to lower temperatures to reduce brittleness and adjust ductility and toughness.

These processes are crucial to ensuring that carbon steel meets the specifications of each application, allowing this material to remain a popular choice in various industries due to its adaptability and cost efficiency.