Aluminum Alloy 6061 (Al 6061-T6, 6061-T651, 6061-T4)

Al-6061 aluminum alloy is a general-purpose structural alloy developed by Alcoa in 1935. The temper designations mainly have 6061-T4, T451, Al 6061-T6, 6061-T651, etc. The main alloying elements are magnesium (Mg) and silicon (Si). The silicon and magnesium content in this alloy is close to magnesium silicide (Mg2Si), therefore it is a heat-treated wrought alloy.

6061-T6 aluminum has a minimum yield strength of 35 ksi (240 MPa), which is about the same as A36 steel. This strength, combined with its light weight (about 1/3 that of steel), makes it particularly suitable for structural applications where static loads are a concern. Compared to 7000 (e.g., alloy 7075) and 2000 (e.g., alloy 2024) series aluminum, AA6061, although lower in strength, is less sensitive to solution heat treatment and temper variation.

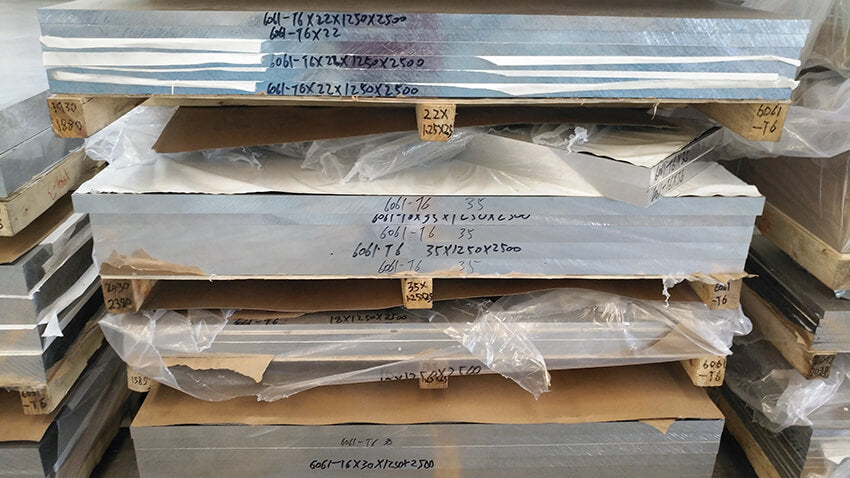

Because 6061 aluminum alloy is easy to extrude, it can provide a variety of product shapes, such as sheets, strips, plates, bars, forgings, tubes, pipes, wires, extruded parts and structural shapes.

6061 aluminum has good corrosion resistance, mechanical properties, formability, weldability and machinability. Generally suitable for medium to high strength requirements and has good toughness. Applications range from food and beverage packaging, electronics and appliances, architectural decoration, transportation to aerospace components. Alloy 6082, popular in Europe, is slightly stronger than AA6061 and has similar uses.

The abbreviations Al-6061 and AA6061 in this article are the same material. Al-Aluminum; AA-the Aluminum or Aluminum Alloy Association.

Properties, datasheet and specifications of 6061 aluminum alloy.

The following tables and lists summarize the properties, data sheets and specifications of 6061 aluminum, including chemical composition, physical and mechanical properties, welding, hardness, machinability, heat treatment, etc.

Chemical composition

The chemical composition of 6061 aluminum is listed in the following table.

| Chemical Composition AA-6061,% | |||||||||||

| ASTM, SAE AMS | ANSI, Alloy (UNS) | Yes | Fe, ≤ | Ass | Mn, ≤ | mg | Cr | Zn, ≤ | Ti, ≤ | Other elements, each (total), ≤ | Al |

| ASTM B209; ASTM B211; ASTM B221; ASTM B210; ASTM B308/B308M; ASTM B308/B308M; ASTM B308/B308M; ASTM B241/B241M; SAE AMS 4025; SAE AMS 4026; SAE AMS 4027; SAE AMS 4117 |

6061 (UNS A96061) | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 (0.15) | Remaining |

Notes (various standards of 6061 aluminum):

- ASTM B209: Aluminum and aluminum alloy sheets and plates.

- ASTM B211: Cold-rolled or finished bars, rebar, and wire.

- ASTM B221: Bars, rebar, wire, profiles and extruded tubes.

- ASTM B210: Seamless drawn aluminum and aluminum alloy tubes.

- ASTM B308/B308M: AL 6061-T6 aluminum structural profiles.

- ASTM B241/B241M: Seamless Tube and Seamless Extruded Tube.

- SAE AMS 4025: Plates and Plates; Temperament O; Annealed.

- SAE AMS 4026: Plates and Plates; Temper T4, T42, T451 (sheet -T4, -T451), solution heat treated and aged naturally.

- SAE AMS 4027: Plates and Plates; Temper T6 Aluminum, T62, T651 (Sheet AL 6061-T6, Plate 6061T651) Solution and Precipitation heat treated.

- SAE AMS 4117: Cold-rolled or finished bars, rebar, wire, and flash-welded rings; (AL 6061-T6 Aluminum, 6061-T651).

Physical Properties of Aluminum 6061

The physical properties of 6061 aluminum are provided in the following lists, including density, melting point, coefficient of thermal expansion, modulus of elasticity, thermal conductivity, specific heat capacity, electrical conductivity, and electrical resistance.

Grades:

- 10 -6 ·K -1 = 10 -6 /K = 1 μm/m·°C

- 1Ω mm²/m = 1 μΩ m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1kN/mm2

- 1 MPa = 1 N/mm2

The melting range shown applies to forged products with a thickness of 6.35 mm (1/4 in.) or greater.

Specific gravity: 2.7

| Physical Properties of Al-6061 Aluminum | |||||||||

| ASTM | League and Temperament | Density, g/cm3 (lb/in.3) | Melting point, °C (°F) | Specific heat capacity, J/kg·K (Btu/lb ·°F) | Coefficient of thermal expansion, 10 -6 /K (μin./in. ·°F) | Thermal diffusivity, mm2/s | Thermal conductivity, W/m·°C (Btu∙in/h∙ft²∙°F) | Electrical conductivity, equal volume (equal weight), % IACS | Electrical resistivity, Ω·mm2/m (Ω·circ mil/ft) |

| ASTM B209; ASTM B210; ASTM B221; ASTM B241; ASTM B308; SAE AMS 4027; SAE AMS 4117; SAE AMS 4025; SAE AMS 4026 |

6061-O | 2.70 (0.098) | 580-650 (1080-1205) | 896 (0.214) at 20°C (68°F) | 23.6 (13.1) at 20-100°C (68-212°F) | 66 | 180 (1250) to 25°C (77°F) | 47 (155) to 20°C (68°F) | 0.0365 (22) at 20°C (68°F) |

| 6061-T4 | 154 (1070) at 25°C (77°F) | 40 (132) to 20 °C (68 °F) | 0.043 (26) at 20°C (68°F) | ||||||

| 6061-T6 | 167 (1160) at 25°C (77°F) | 43 (142) to 20°C (68°F) | 0.040 (24) at 20°C (68°F) | ||||||

Mechanical properties

The mechanical properties of 6061-T6 aluminum are listed in the following tables, including yield strength (yield stress), ultimate tensile strength, shear strength, modulus of elasticity, modulus of elasticity, etc.

The following mechanical properties are the average value of various product sizes, shapes and manufacturing methods, so the properties cannot be guaranteed. They are only used as a basis for alloy comparison and tempering and should not be specified as engineering requirements or used for design purposes.

| Mechanical Properties of Aluminum 6061, Part 1 | |||||

| Aluminum alloy and quenching | Ultimate tensile strength, MPa (ksi) | Yield strength, MPa (ksi) | Elongation by 50 mm (2 in.), ≥% | Brinell hardness, HB (load of 500 kgf 10 mm sphere) | |

| 1.6 mm (1/16 in.) thick sample | 12.5 mm (1/2 in.) thick sample | ||||

| 6061-O | 125 (18) | 55 (8) | 25 | 27 | 30 |

| 6061-T4, T451 | 240 (35) | 145 (21) | 22 | 22 | 65 |

| 6061-T6, T651 | 310 (45) | 275 (40) | 12 | 15 | 95 |

| Alclad 6061-O | 115 (17) | 50 (7) | 25 | – | – |

| Alclad 6061-T4, T451 | 230 (33) | 130 (19) | 22 | – | – |

| Alclad 6061-T6, T651 | 290 (42) | 255 (37) | 12 | – | – |

| Mechanical Properties of Aluminum 6061, Part 2 | |||

| Aluminum alloy and quenching | Ultimate shear strength, MPa (ksi) | Modulus of elasticity, GPa (10 6 psi) | Fatigue resistance limit, MPa (ksi) |

| 6061-O | 85 (12) | 69 (10) | 60 (9) |

| 6061-T4, T451 | 165 (24) | 69 (10) | 95 (14) |

| Al 6061-T6, T651 | 205 (30) | 69 (10) | 95 (14) |

| Alclad 6061-O | 75 (11) | 69 (10) | – |

| Alclad 6061-T4, T451 | 150 (22) | 69 (10) | – |

| Alclad 6061-T6, 6061-T651 | 185 (27) | 69 (10) | – |

Notes for modulus of elasticity: The average of the tensile modulus (Young's modulus) and compression. The compression modulus is about 2% greater than the tensile modulus (Young's modulus).

| Typical mechanical properties of 6061 aluminum at different temperatures | ||||

| League and temperament | Temperature, °C (°F) | Ultimate tensile strength, MPa (ksi) | 0.2% Compensated Yield Strength | Elongation by 50 mm (2 in.), ≥%, |

| 6061-T6, 6061-T651 |

-195 (-320) | 415 (60) | 325 (47) | 22 |

| -80 (-112) | 338 (49) | 290 (42) | 18 | |

| 0 (-18) | 325 (47) | 283 (41) | 17 | |

| 24 (75) | 310 (45) | 275 (40) | 17 | |

| 100 (212) | 290 (42) | 262 (38) | 18 | |

| 150 (300) | 235 (34) | 215 (31) | 20 | |

| 205 (400) | 130 (19) | 103 (15) | 28 | |

| 250 (500) | 52 (7.5) | 35 (5) | 60 | |

| 315 (600) | 32 (4.6) | 19 (2.7) | 85 | |

| 370 (700) | 21 (3) | 12 (1.8) | 95 | |

Mechanical Properties of 6061-T6 Aluminum in SAE AMS and ASTM Standard

| Mechanical properties of 6061 aluminum – bars, rods, wires, profiles and extruded tubes | ||||||

| Standard | Aluminum alloy and quenching | Specified diameter or thickness, in. | Area, in2 | Tensile strength, ksi, ≥ (unless otherwise specified) | Yield strength (0.2% shift), ksi, ≥ (unless otherwise specified) | Stretch by 2 in. or 4xDiameter, ≥, % |

| ASTM B221 | 6061-O | all | all | 22, ≤ | 16, ≤ | 10 |

| 6061-T1 | ≤ 0.625 | all | 26.0 | 14.0 | 16 | |

| 6061-T4, T4510, T4511 | all | all | 26.0 | 16 | 16 | |

| 6061-T42 | all | all | 26.0 | 12 | 16 | |

| 6061-T51 | ≤ 0.625 | all | 35.0 | 30 | 8 | |

| 6061-T6, T62, T6510, T6511 | ≤ 0.249 | all | 38 | 35 | 8 | |

| ≥0.250 | all | 38 | 35 | 10 | ||

| Mechanical Properties of Aluminum 6061 – Designed Seamless Tubes | Stretch by 2 in. or 4xDiameter, ≥, % | |||||

| Standard | Aluminum alloy and quenching | Specified diameter or thickness, in. | Tensile strength, ksi, ≥ (unless otherwise specified) | Yield strength (0.2% shift), ksi, ≥ (unless otherwise specified) | Full Section Sample | Cropped sample |

| ASTM B210; AMSWWT700/6 |

6061-O | 0.018-0.500 | 22, ≤ | 14, ≤ | 15 | 15 |

| 6061-T6, T62 | 0.025-0.049 | 30.0 | 16.0 | 16 | 14 | |

| 0.050-0.259 | 30.0 | 16.0 | 18 | 16 | ||

| .260-.500 | 30.0 | 16.0 | 20 | 18 | ||

| 6061-T42 | 0.025-0.049 | 30.0 | 14.0 | 16 | 14 | |

| 0.050-0.259 | 30.0 | 14.0 | 18 | 16 | ||

| .260-.500 | 30.0 | 14.0 | 20 | 18 | ||

| 6061-T6, T62 | 0.025-0.049 | 42.0 | 35.0 | 10 | 8 | |

| 0.050-0.259 | 42.0 | 35.0 | 12 | 10 | ||

| .260-.500 | 42.0 | 35.0 | 14 | 12 | ||

| Mechanical properties of 6061 aluminum – cold rolled or finished bars, rebars and wires | |||||

| Standard | Aluminum alloy and quenching | Specified diameter or thickness, in. | Tensile strength, ksi, ≥ (unless otherwise specified) | Yield strength (0.2% shift), ksi, ≥ (unless otherwise specified) | Stretch by 2 in. or 4xDiameter, ≥, % |

| ASTM B211 | 6061-O | ≤0.124 | 20, ≤ | – | – |

| 0.125-8.000 | 18 | ||||

| 6061-T4, T451 | ≤ 0.124 | 30 | – | – | |

| 0.125-8.000 | 30 | 16 | 18 | ||

| 6061-T42 | 0.125-8.000 | 30 | 14 | 18 | |

| 6061-T6, T62, T651 | ≤ 0.124 | 42 | – | – | |

| 0.125-8.000 | 42 | 35 | 10 | ||

| 6061-T89, T94 | ≤ 0.374 | 54 | 47 | – | |

| Mechanical Properties of Aluminum 6061 – Plate and Sheet | ||||||

| Standard | Aluminum alloy and quenching | Specified thickness, in. | Tensile strength, ksi, ≥ (unless otherwise specified) | Yield strength (0.2% shift), ksi, ≥ (unless otherwise specified) | Stretch by 2 in. or 4xDiameter, ≥, % | Bending diameter factor, N |

| ASTM B209 | 6061-O | 0.006-0.007 | ≤22 | 12.0 | 10 | 0 |

| 0.008-0.009 | 12 | 0 | ||||

| 0.010-0.020 | 14 | 0 | ||||

| 0.021-0.128 | 16 | |||||

| 0.129-0.249 | 18 | 1 | ||||

| 0.250-0.499 | 18 | two | ||||

| 0.500-1.000 | 18 | 3 | ||||

| 1,001-3,000 | 16 | – | ||||

| 6061-T4 | 0.006-0.007 | 30.0 | 16.0 | 10 | two | |

| 0.008-0.009 | 12 | two | ||||

| 0.010-0.020 | 14 | two | ||||

| 0.021-0.249 | 16 | 3 | ||||

| 6061-T451 | 0.250-0.499 | 30.0 | 16.0 | 18 | 4 | |

| 0.500-1.000 | 18 | – | ||||

| 1,001-3,000 | 16 | – | ||||

| 6061-T42 | 0.006-0.007 | 31.0 | 14.0 | 10 | two | |

| 0.008-0.009 | 12 | two | ||||

| 0.010-0.020 | 14 | two | ||||

| 0.021-0.249 | 16 | 3 | ||||

| 0.250-0.499 | 18 | 4 | ||||

| 0.500-1.000 | 18 | – | ||||

| 1,001-3,000 | 16 | – | ||||

| 6061-T6, T62 | 0.006-0.007 | 42.0 | 35.0 | 4 | two | |

| 0.008-0.009 | 6.0 | two | ||||

| 0.010-0.020 | 8.0 | two | ||||

| 0.021-0.036 | 10.0 | 3 | ||||

| 0.037-0.064 | 10.0 | 4 | ||||

| 0.065-0.128 | 10.0 | 5 | ||||

| 0.129-0.249 | 10.0 | 6 | ||||

| 6061-T62, T651 | 0.250-0.499 | 42.0 | 35.0 | 10 | 7 | |

| 0.500-1.000 | 42.0 | 9 | – | |||

| 1,001-2,000 | 42.0 | 8 | – | |||

| 2001-4000 | 42.0 | 6 | – | |||

| 4,001-6,000 | 40.0 | 6 | – | |||

| 6061F | 0.250-3.000 | – | – | – | – | |

| Alclad 6061-O | 0.010-0.020 | ≤20 | 12.0 | 14 | – | |

| 0.021-0.128 | ≤20 | 12.0 | 16 | – | ||

| 0.129-0.499 | ≤20 | 12.0 | 18 | – | ||

| 0.500-1.000 | ≤22 | – | 18 | – | ||

| 1,001-3,000 | ≤22 | – | 16 | – | ||

| Alclad 6061-T4 | 0.010-0.020 | 27.0 | 14.0 | 14 | – | |

| 0.021-0.249 | 27.0 | 14.0 | 16 | – | ||

| Alclad 6061-T451 | 0.250-0.499 | 27.0 | 14.0 | 18 | – | |

| 0.500-1.000 | 30.0 | 16.0 | 18 | – | ||

| 1,001-3,000 | 30.0 | 16.0 | 16 | – | ||

| Alclad 6061-T42 | 0.010-0.020 | 27.0 | 12.0 | 14 | – | |

| 0.021-0.249 | 27.0 | 12.0 | 16 | – | ||

| 0.250-0.499 | 27.0 | 12.0 | 18 | – | ||

| 0.500-1.000 | 30.0 | 14.0 | 18 | – | ||

| 1,001-3,000 | 30.0 | 14.0 | 16 | – | ||

| Alclad 6061-T6, T62 | 0.010-0.020 | 38.0 | 32.0 | 8 | – | |

| 0.021-0.249 | 38.0 | 32.0 | 10 | – | ||

| Alclad 6061-T6, T62 | 0.250-0.499 | 38.0 | 32.0 | 10 | – | |

| 0.500-1.000 | 42.0 | 35.0 | 9 | – | ||

| 1,001-2,000 | 42.0 | 35.0 | 8 | – | ||

| 2001-4000 | 42.0 | 35.0 | 6 | – | ||

| 4,001-5,000 | 40.0 | 35.0 | 6 | – | ||

| Alclad 6061 F | 0.250-3.000 | – | – | – | – | |

6061 Aluminum Alloy Welding

Al-6061 alloy is easy to weld and connect by various methods. Generally welded with ER4043; For best color matching, ER5356 is recommended.

The following table summarizes common similar metal welded joints made with FRW inertial drive.

Grades:

- Metal Loss: The total shortening of the part during the welding process.

- Total Time: The sum of the heating time plus the welding time.

| Inertia-driven friction stir welding parameters of two 25 mm (1 in.) diameter rods made of similar metals. | ||

| Working metal | Spindle speed, Rev/Min | 5700 |

| 6061 Aluminum Alloy | Axial Force, KN (lbf x 10 3 ) | 31 (7) |

| Flywheel size, kg·m2 (lb·ft2) | 0.13 (3) | |

| Welding energy, KJ (ft·lbf x 10 3 ) | 23 (17) | |

| Metal loss, mm (in.) | 3.8 (0.15) | |

| Total time, s | 1 | |

The following table provides the parameters used for inertia welding of several common combinations of different materials.

Note for Axial Force: A force of 22 KN (5000 lbf) is applied during the heating phase of welding; the force near the end of the weld is subsequently increased to 67 KN (15,000 LBF).

| Parameters of inertia-driven friction stir welding of two 25 mm (1 in.) diameter rods made of dissimilar metals. | ||

| Working metal | Spindle speed, Rev/Min | 5500 |

| Aluminum 6061 to Type 302 Stainless | Axial Force, KN (lbf x 10 3 ) | 22 (5) |

| 67 (15) | ||

| Flywheel size, kg·m2 (lb·ft2) | 0.16 (3.9) | |

| Welding energy, KJ (ft·lbf x 10 3 ) | 27 (20) | |

| Metal loss, mm (in.) | 5.1 (0.2) | |

| Total time, s | 3 | |

| Effect of welding conditions on the welding strength of AL-6061 alloy | |||||||||||

| Base metal alloy and temper | Thickness, mm (in.) | Welding process and conditions | As a soldier | Aged only after welding | Heat-treated and aged post-weld solution | ||||||

| Tensile strength, MPa (ksi) | 0.2%, yield strength, MPa (ksi) | Elongation by 51 mm (2 in.), ≥% | Tensile strength, MPa (ksi) | 0.2%, yield strength, MPa (ksi) | Elongation by 51 mm (2 in.), ≥% | Tensile strength, MPa (ksi) | 0.2%, yield strength, MPa (ksi) | Elongation by 51 mm (2 in.), ≥% | |||

| 6061-T6 (4043 filler) | 3.2 (1/8) | DCEN GTAW, 15 mm/s (35 in./min) | 248 (36) | 165 (24) | 6 | – | – | – | 303 (44) | 276 (40) | 5 |

| 6061-T4 (4043 filler) | 3.2 (1/8) | DCEN GTAW, 8.5 mm/s (20 in/min) | 234 (34) | 145 (21) | 8 | 283 (41) | 179 (26) | 3 | 303 (44) | 276 (40) | 5 |

| 6061-T6 (4043 filler) | 6.4 (1/4) | Automatic GMAW, one pass per side 17 mm/s (40 in./min) | 255 (37) | 138 (20) | 6 | – | – | – | 296 (43) | 276 (40) | 5 |

| 6061-T4 (4043 filler) | 76 (3) | Automatic GMAW, double-V multipass | 172 (25) | 90 (13) | 10 | – | – | – | 234 (34) | – | 4 |

| 6061-T6 (filler 4643) | 76 (3) | Automatic GMAW, double-V multipass | 186 (27) | 97 (14) | 13 | – | – | – | 310 (45) | 276 (40) | 4 |

| Typical mechanical properties of gas shielded arc welded butt joints in selected heat treated and heat treatable aluminum alloys. | |||||||||

| Base alloy and tempering | Filler alloy | As a soldier | Heat-treated and aged post-weld solution | ||||||

| Tensile strength | 0.2% yield strength, at 50.8 mm (2 in.) | Stretching | Tensile strength | 0.2% yield strength, at 50.8 mm (2 in.) | Stretching | ||||

| MPa (ksi) | MPa (ksi) | Tensile, ≥% in 50.8 mm (2 in.) | Free curvature, % | MPa (ksi) | MPa (ksi) | Tensile, ≥% in 50.8 mm (2 in.) | Free curvature, % | ||

| AA-6061-T4 | 4043 | 186 (27) | 124 (18) | 8 | 16 | 241 (35) ① | 165 (24) ① | 3① | – |

| AA-6061-T6 | 4043 | 186 (27) | 124 (18) | 8 | 16 | 303 (44)② | 276 (40)② | 5② | 11② |

| AA-6061-T6 | 5356 | 207 (30) | 131 (19) | 11 | 25 | – | – | – | – |

Grades:

- ① Postweld only artificially aged.

- ② For thicknesses greater than 19 mm (3/4 in.), 4643 filler is required.

6061 Aluminum Heat Treatment

| Typical heat treatments for 6061 aluminum alloy rolled products | ||||||

| aluminum alloy | products | Solution heat treatment | Precipitation heat treatment | Temperament designation | ||

| Metal temperature, °C (°F) | Temperament designation | Metal temperature, °C (°F) | About. time at temperature, h | |||

| AA6061 | Sheet | 530 (985) | T4 | 160 (320) | 18 | T6 |

| T42 | T62 | |||||

| Plate | 530 (985) | T4 (floor plate only), T451 |

160 (320) | 18 | T6 (floor plate only), T651 |

|

| T42 | 160 (320) | 18 | T62 | |||

| Cold rolled or finished wire, rod and bar | 530 (985) | T4, T3, T4, T4, T451 |

160 (320), An alternative treatment consisting of 8 hours at 170 (340) can also be used. | 18 | T6, T89, T913, T94, T651 |

|

| T42 | T62 | |||||

| Extruded rod, bar, profiles and tube | Quenched directly from the extrusion press. | T1 | 175 | 8 | T51 | |

| 530 (985) | T4, T4510, T4511 |

175 | 8 | T6, T6510, T6511 |

||

| 530 (985) | T42 | 175 | 8 | T62 | ||

| Structural Profiles | 530 (985) | T4 | 175 | 8 | T6 | |

| pipe | 530 (985) | T4 | 175 | 8 | T6 | |

| Drawn tube | 530 (985) | T4 | 160 | 18 | T6 | |

| T42 | 160 | 18 | T62 | |||

| Die and forge by hand | 530 (985) | T4 | 175 | 8 | T6 | |

| Coiled Rings | 530 (985) | T4 | 175 | 8 | T6 | |

| T452 | 175 | 8 | T652 | |||

Annealing AA-6061

Typical full annealing treatment (condition O): The annealing process is a medium process. Heat to 415°C (775°F) for 2 to 3 hours and then cool slowly (28°C/h) to 260°C (500°F). Intermediate annealing for cold work removal shall be performed at 343°C (650°F). Cooling time and rate are not critical.

Aging of 6061 Aluminum

Sheets, plates, cold rolled or rolled wires, rods, bars and drawn tubes of 6061 aluminum alloy are aged at a metal temperature of 160°C (320°F) and held for 18h. Rods, rods, profiles and extruded tubes; dies and forged by hand, the rolled rings are aged at a metal temperature of 175°C (345°F) and held for 8 hours.

Al 6061 Alloy Corrosion Resistance

Al 6061 alloy has excellent corrosion resistance in atmospheric conditions and good corrosion resistance in seawater. This alloy also has a good finish and a good reaction to anodic oxidation. However, where appearance is crucial, consider using alloy 6060 or 6063.

Typical Applications of 6061 Aluminum Alloy

Representative applications of 6061 aluminum alloy include aerospace and electrical installations as well as communications. They are also widely used in automated machine parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder pads, etc.

- Aerospace: 6061 aluminum alloy can be used to make aircraft skins, fuselage structures, beams, rotors, propellers, fuel tanks, landing gear skin and pylons, as well as rocket forging rings, spacecraft skin , etc.

- Transportation: 6061 aluminum alloy also used for automobiles, subway cars, railway passenger cars, high-speed passenger car body structural materials, doors and windows, shelves, automobile engine parts, air conditioners, radiators, dashboards bodywork, wheels and ship materials.

- Packaging: 6061 aluminum alloy is also used as metal packaging material in the form of thin plates and sheets, made into cans, lids, bottles, barrels, packaging sheets, which are widely used in packaging of beverage, food, cosmetics, medicines, cigarettes, industrial products, etc.

- Printing: Mainly used to make PS boards. Aluminum-based PS boards are a new type of material for the graphics industry. They are used for automatic plate making and printing.

- Architectural decoration: 6061 alloy is mainly used in building frames, doors and windows, false ceilings, metal curtains, perforated metal sheets, decorative surfaces, etc., such as various architectural doors and windows, curtain wall aluminum profiles, aluminum curtain wall panels, profiled panels, checkered panels, color coated aluminum panels, etc.

- Electronic household appliances: 6061 also used in various busbars, wiring, conductors, electrical components, refrigerators, air conditioners, cables and other fields.

6061 aluminum alloy equivalent

Aluminum 6061 equivalent to European EN standard (German DIN EN, British BSI EN, France NF EN), ISO, Japanese JIS and Chinese standard GB (for reference).

Notes: DIN 1725-1 has been replaced by DIN EN 573-3.

| AA-6061 Aluminum Equivalent Material | |||||||||||||

| USA | European Union | Germany | China | Japan | ISO | ||||||||

| Standard | Note (UNS) | Standard | Note | Standard | Numeric (chemical symbols) | Standard | Aluminum name (material number) | Standard | Note | Standard | Note | Standard | Note |

| AA; ASTM B209; ASTM B211; ASTM B221; ASTM B210; ASTM B308/B308M; ASTM B241/B241M |

6061 (UNS A96061) | SAE AMS 4025; SAE AMS 4026; SAE AMS 4027; SAE AMS 4117 |

6061 | EN 573-3 | EN AW-6061 (EN AW-AlMg1SiCu) | DIN 1725-1 | AlMgSi1Cu (3.3211) | GB/T 3190; GB/T 3880.2 |

6061 | JIS H4000; JIS H4040 |

6061 | ISO 209 | AW-6061 |

Related materials: SAE 5160 Steel, Type 302 Stainless Steel, AISI 904L Stainless Steel, AISI 304 Stainless Steel, SAE 1080 Steel, X5CrNi18-10 (1.4301)

1comment

Prezados,

Eu tenho uma dúvida , aqui na empresa utilizamos barras de alumínio Liga de Alumínio: 6061-T4 com as seguintes dimensões:

Liga de Alumínio: 6061-T4

Dimensões da Barra: 3/8” x 1/2” 0,1 mm

Comprimento: 920 mm 1 mm

Nós dobramos em formato de gancho e depois é colocado em estufa para fazer têmpera para ganhar dureza (efeito mola). Eu gostaria de saber qual a temperatura ideal para fazer este tratamento e por quantas horas?

Atualmente fazemos este processo a 225 graus por 4 horas, fico grato se poderem sanar esta dúvida.

Grato,

Emerson