Among construction and manufacturing materials, few are as ubiquitous and vital as Carbon steel . This robust and versatile material is the backbone of countless structures and products, playing a crucial role in almost every aspect of civil and industrial construction. But what exactly is carbon steel? And what makes it so indispensable for so many different applications?

Carbon steel is more than just a metal alloy; it is a foundation upon which our modern society is built. With its unique properties, which can be carefully tuned to meet a wide range of specific needs, carbon steel has become an essential component in a variety of industries. From the construction of buildings and bridges to the manufacture of automobiles and machinery, the applications of carbon steel are as diverse as they are essential.

Let's understand and seek the highest level of knowledge about Carbon Steel . Definitions, how it is produced, its unique properties and of course the countless ways in which it is used around the world. Discover the fundamental importance of carbon steel in engineering and construction, and how this modest material continues to shape innovation and progress in many fields.

What is Carbon Steel?

Carbon steel, in essence, is an alloy composed predominantly of iron, with a percentage of carbon varying between 0.05% and 2.1% by weight. This variation in carbon content not only defines the mechanical properties of the steel, but also determines its classification into low, medium and high carbon. The secret of carbon steel lies in its incredible versatility: by adjusting the carbon content and manufacturing process, you can significantly change its hardness, ductility, tensile strength and responsiveness to heat treatment.

Carbon steel, fundamental in engineering and construction, is characterized by its unique composition and adaptable properties. The alloy, predominantly ferrous, incorporates carbon in a fraction that determines its mechanical and processing characteristics, offering a range of properties that can be precisely adjusted for specific applications.

Detailed composition and influence of Carbon

The composition of carbon steel varies significantly, with the carbon content ranging between 0.05% and 2.1% by weight. This variation is crucial, as carbon acts as a strengthening agent within the iron matrix, directly influencing the microstructure of the steel and, consequently, its physical properties.

Classifying carbon steel into low, medium and high carbon categories is crucial to understanding its specific properties and applications. Each type has distinct characteristics that make it suitable for different uses in industry and construction. Here's a detailed exploration of these categories:

Low Carbon (Smooth Steel)

- Composition : Contains up to 0.3% carbon. This is the most common type of carbon steel, characterized by its great malleability and ductility.

- Properties : Due to the low carbon content, it is easy to weld and form, making it ideal for manufacturing processes that require extensive molding or welding.

- Applications : Widely used in civil construction for metallic structures, vehicle sheets, pipes and as a base for coated or painted steel. Its properties also make it suitable for machine parts that are not subject to great stress.

Medium Carbon

- Composition : It has a carbon content that varies from 0.3% to 0.6%. This balance offers an improvement in strength and load capacity compared to low carbon steel, at the cost of reduced ductility.

- Properties : Offers a good balance between strength, ductility and toughness. It is stronger and harder than low carbon steel, but still has a good ability to be mechanically worked.

- Applications : Commonly used in automotive components, such as axles and gears, machine parts, structures that require greater strength and in forged products. Requires heat treatments to achieve desired properties.

High Carbon

- Composition : Contains 0.6% to 1% carbon, and some varieties can have up to 2.1% carbon. This high concentration of carbon gives the steel great hardness and resistance.

- Properties : This type of steel is very hard and resistant, but this same hardness reduces its ductility. It is more difficult to weld and work with than lower carbon types.

- Applications : Ideal for the manufacture of cutting tools such as drills and saws, as well as springs, high-quality blades and any component that requires high resistance to wear and fatigue. Heat treatment is crucial to develop its specific properties.

Each type of carbon steel offers a set of properties that meet specific engineering and design needs. By choosing the appropriate type of carbon steel, engineers and designers can optimize the function, performance and longevity of the components and structures they create, ensuring that each project takes full advantage of the unique characteristics of this versatile material.

Manufacturing process and heat treatment

The manufacturing process and heat treatments are fundamental to determining the properties of carbon steel, adapting it to various industrial and commercial applications. Let's explore more deeply how these processes influence the microstructure and characteristics of carbon steel.

Carbon steel is produced mainly through two basic methods: manufacturing using a blast furnace, followed by rolling, and forging.

-

Blast Furnace and Lamination :

- Pig Iron Production : The first step is the production of pig iron, which is carried out in the blast furnace. Iron ore, coke and limestone are the main raw materials.

- Conversion to Steel : The pig iron is then converted to steel in an oxygen converter, where the carbon is reduced to desired levels.

- Rolling : Steel is heated and passed through rollers to form sheets, bars, or other shapes. Rolling can be hot, where the steel is deformed at high temperatures, or cold, for a better finish and precise dimensional tolerances.

-

Forging :

- Hot Forging : In this process, steel is heated to high temperatures and then mechanically deformed to form specific shapes. This changes the internal structure of the steel, increasing its strength and toughness.

Thermal treatments

Heat treatments are critical processes used to alter the microstructure of carbon steel to achieve desired mechanical properties such as hardness, ductility and wear resistance. The main heat treatments include:

-

Austenitization:

- The steel is heated to a temperature that transforms its crystalline structure into austenite, a phase that allows for a more uniform distribution of carbon in the iron.

- This process is essential to prepare the steel for quenching, as austenite transforms into martensite during rapid cooling, a key component in obtaining high hardness.

-

Temper:

- After austenitization, the steel is quickly cooled, usually in water or oil. This abrupt cooling transforms austenite into martensite, a much harder and more resistant phase.

- Quenching increases the hardness and strength of steel, but also makes it more brittle.

-

Tempering:

- To reduce the brittleness introduced by quenching, the steel is heated to lower temperatures (between 150 to 650 degrees Celsius, depending on the steel). This process allows you to adjust hardness, reducing brittleness while improving ductility and toughness.

- Tempering is crucial to balancing the properties of steel, making it suitable for practical applications that require a combination of strength, ductility and impact resistance.

The manufacturing process and heat treatments of carbon steel are essential to produce a material that not only meets strength and durability specifications but also the flexibility and ductility demands for various industrial applications. Each step of the process is carefully controlled to ensure that the carbon steel produced can be used in everything from construction to high-precision components in machines and vehicles.

Advanced technical applications

The ability to tune the mechanical properties of carbon steel makes it indispensable in applications that require precise technical specifications. From load-bearing structures that take advantage of its excellent weldability and strength, to high-precision components in the automotive and aerospace industries that benefit from its wear resistance and toughness, carbon steel is a key material in modern engineering.

Additionally, continued innovation in carbon steel metallurgy is opening new frontiers in sustainability and performance, with the development of high-strength low alloy (HSLA) alloys and production techniques that minimize environmental impact without compromising quality or functionality.

Fundamental importance in various sectors

Carbon steel , due to its adaptability and distinct mechanical properties, finds application in a wide range of sectors, demonstrating its versatility and importance. Here are some of its most significant applications, illustrated with concrete examples:

Construction

Carbon steel is a key material in civil construction, used both in the main structure of buildings and in specific construction components. For example:

- Steel Structures : Beams, columns and trusses made from low-carbon steel form the skeleton of commercial and residential buildings, warehouses and bridges due to their strength and flexibility.

- Reinforcement for Concrete : Low carbon steel is often used as reinforcement within concrete to increase its tensile strength, essential in slabs, columns and foundations.

Automotive industry

In this sector, carbon steel plays a crucial role, from vehicle structures to specific components:

- Bodies and Chassis : Low carbon steel is used in car bodies and chassis, offering an ideal combination of strength, malleability and impact absorption capacity.

- Mechanical Components : Parts such as axles, gears, and suspension components are often made from medium to high carbon steel, which provides the strength and hardness needed to withstand operational stress.

Manufacturing of Tools and Utensils

High carbon steel is preferred for making tools and utensils because of its ability to maintain a sharp edge and resist wear:

- Hand Tools : Screwdrivers, pliers and hammers are made from carbon steel, benefiting from its durability.

- Cutting Tools : Knife, drill and saw blades require high carbon to maintain sharpness under intensive use.

Energy Sector

Carbon steel is essential in the energy sector, especially in oil and gas infrastructure:

- Piping and Ducting : Low to medium carbon steel is used to manufacture pipes and ducts that transport oil, natural gas and other fluids under pressure, chosen for its mechanical and corrosion resistance under controlled conditions.

Agriculture and Heavy Equipment

Agricultural machinery and heavy construction equipment depend on the strength of carbon steel:

- Agricultural Machinery : Tractors, plows and harvesters rely on carbon steel components to withstand harsh working conditions and resist wear and tear.

- Construction Equipment : Excavators, cranes and bulldozers use carbon steel in support structures and critical mechanical components.

Maritime Sector

In shipbuilding, carbon steel is used for its strength and ability to withstand the dynamic forces of the sea:

- Ship Hulls : Much of the hull and superstructure of commercial and military ships is constructed using carbon steel, protected against corrosion by special coatings.

These applications underscore the versatility of carbon steel, demonstrating its ability to meet a wide range of technical and operational requirements across diverse industry sectors and beyond.

In short, carbon steel is not just a material ; it is a fundamental element that drives innovation, safety and sustainability across a diverse range of industries. Its ubiquity in so many aspects of modern life is a testament to its intrinsic importance and the vital role it plays in shaping the world around us.

Difference between Carbon Steel and other types of steel

To differentiate carbon steel from other types of steel, it is essential to understand the unique characteristics that define its composition and mechanical properties, as well as its functionality in diverse applications. Carbon steel is distinguished mainly by its variable carbon content , which directly influences its strength, ductility and heat treatment capacity, contrasting with other categories of steel, such as stainless steel, alloy steel and tool steel.

Carbon Steel vs. Stainless steel

- Composition : While carbon steel is characterized by its carbon content, stainless steel is defined by the addition of chromium (at least 10.5%) and nickel, which provide resistance to corrosion.

- Properties : Stainless steel is highly resistant to oxidation and corrosion, making it ideal for aggressive environments or for applications that require hygiene, such as medical equipment and kitchen utensils. Carbon steel, although it can be treated to improve its corrosion resistance, often requires additional protection or maintenance in corrosive environments.

Carbon Steel vs. Alloy Steel

- Composition : Alloy steels are characterized by the addition of alloying elements other than carbon, such as chromium, nickel, molybdenum and vanadium, in significant quantities to improve their mechanical and wear resistance properties.

- Properties : Alloy steels offer advantages in terms of wear resistance, fatigue resistance and the ability to operate in extreme temperatures. Carbon steel, although versatile, does not achieve the same levels of performance in extreme conditions without special treatments or coatings.

Carbon Steel vs. Tool Steel

- Composition : Tool steels are a category of highly specialized alloy steels developed to form cutting tools, molds and dies. They contain varying proportions of tungsten, molybdenum, cobalt and vanadium to provide high hardness and heat resistance.

- Properties : Compared to carbon steel, tool steel offers superior hardness and resistance to deformation under heat. Carbon steel is preferred for structural and general engineering applications due to its weldability, ductility and cost-effectiveness, while tool steel is chosen for applications that require high precision and durability under mechanical or thermal stress.

Uniqueness of Carbon Steel

The uniqueness of carbon steel lies in its adaptability and ability to meet a wide range of engineering needs with relatively few changes to its composition. Its economical manufacturing, coupled with the ability to significantly alter its mechanical properties through adjustments in carbon composition and heat treatments, makes it a versatile and fundamental choice for construction, mechanical manufacturing and many other engineering fields.

Advantages of using carbon steel, durability, resistance and cost-benefit.

Carbon steel, with its wide applicability and technical characteristics, offers a series of advantages that make it a preferred material in many engineering and design projects. Here are the main advantages of using carbon steel:

1. Durability and Longevity

- High Strength : The inherent resistance of carbon steel against wear, impact and deformation contributes significantly to the longevity of structures and machines.

- Reduced Maintenance : Its durability minimizes the need for frequent maintenance, reducing costs over time.

2. Resistance and Versatility

- Adaptability : The ability to adjust the properties of carbon steel through control of carbon content and heat treatments allows it to be adapted for a wide range of applications.

- Diversity of Use : From building structures to precision components in machinery, carbon steel can be used in different ways and for different purposes.

3. Value for money

- Economically Viable : Compared to other materials with similar properties, carbon steel is generally more affordable, both in terms of initial cost and maintenance over time.

- Production Efficiency : The ease of production and processing of carbon steel also contributes to its cost efficiency.

4. Recyclability and Sustainability

- High Recycling Potential : Carbon steel is 100% recyclable, which allows resources to be reused and the environmental impact of producing new steel to be reduced.

- Contribution to Sustainable Construction : The use of carbon steel in construction projects can contribute to obtaining sustainability certifications, due to its durability, recyclability and energy efficiency in terms of insulation when applied in certain configurations.

5. Ease of Manufacturing and Forming

- Malleability : Low-carbon steel, in particular, is easily formable, making it ideal for manufacturing processes that require forming or bending.

- Weldability : Most types of carbon steel can be easily welded, allowing the construction of complex structures without compromising the integrity of the material.

Importance in Engineering and Sustainable Design projects

The choice of carbon steel in engineering projects is not just limited to its physical and mechanical properties; it extends to its role in promoting sustainable design practices. The ability to recycle and reuse carbon steel without significant loss of quality ensures that it plays a vital role in reducing material waste and minimizing the carbon footprint of construction and manufacturing projects. Furthermore, its durability and resistance help to build structures and products that stand the test of time, reducing the need for frequent replacement and repairs, and contributing to long-term resource savings.

Therefore, carbon steel not only meets the technical and economic criteria of contemporary projects, but also aligns with sustainability and resource efficiency objectives, reinforcing its value in a world increasingly focused on environmental preservation and building a future sustainable.

Recent innovations in the field of carbon steel and how they can expand its applications

Innovations in the field of carbon steel have been fundamental in expanding its applications and improving its performance in various industries. At the same time, continued development in this area points to a promising future where carbon steel can play an even more significant role in technology and sustainability. Here are some of the upcoming innovations and trends related to carbon steel:

Recent innovations

- Low Carbon Production Technologies : Significant advances have been made to reduce the carbon footprint associated with carbon steel production, including the use of renewable energy and carbon capture and storage (CCS) techniques in manufacturing processes.

- Advanced Surface Treatments and Coatings : New surface treatments and coatings are being developed to improve the corrosion and wear resistance of carbon steel, extending its useful life and reducing the need for maintenance.

- High-Strength, Low-Alloy (HSLA) Steels : The introduction of high-strength, low-alloy steels has provided materials with superior mechanical strength without significantly increasing weight, which is especially beneficial in the automotive industry and in the construction of lightweight structures.

Future trends and untapped potential

- Integration with Smart Technologies : Incorporating sensors and smart technologies into carbon steel for structural health monitoring and failure prevention is a promising area. This can lead to safer and more efficient construction and manufacturing systems, with real-time responsiveness to adverse or distressing conditions.

- Expanded Sustainability : Research continues to focus on even more sustainable production methods and increasing the recyclability of carbon steel. The development of closed life cycles, where steel can be recycled indefinitely without loss of quality, is a crucial objective for reducing the environmental impact of the steel industry.

- Renewable Energy Applications : Carbon steel has a vital role to play in renewable energy infrastructures such as wind towers, solar panel structures and hydropower components. The search for lighter, stronger and more economical materials will continue to drive innovations in this area.

- Development of New Alloys : The creation of new carbon steel alloys that offer improved properties, such as superior thermal resistance for high temperature applications or better performance in extremely corrosive environments, is a field of intense research.

Carbon steel, with its vast spectrum of applications and fundamental importance in various industries, is on the threshold of a new era of innovation and application. As we explore its untapped potential and develop new technologies for its production and use, carbon steel is well positioned to continue to be a key material in building a sustainable and technologically advanced future.

Does Carbon Steel rust?

Carbon steel is an alloy of iron and carbon , and because iron is susceptible to oxidation when exposed to oxygen and moisture, carbon steel is also prone to rusting under similar conditions. Rust is a form of corrosion that occurs as a result of the chemical reaction between iron, oxygen and water, forming iron oxides that are commonly known as rust.

The speed and severity of corrosion in carbon steel can vary significantly depending on environmental factors such as the presence of water, salt, humidity and chemical pollutants. To protect carbon steel from corrosion, several prevention methods are commonly used, such as:

- Painting : Applying paint to carbon steel creates a physical barrier that prevents the metal from direct contact with corrosive agents.

- Galvanizing : This process involves coating the steel with a layer of zinc. Zinc offers protection by corroding preferentially to iron, a process known as cathodic protection.

- Coatings : Applying other protective coatings, such as epoxy or plastics, can also help prevent corrosion.

- Surface Treatments : Treatments such as phosphating increase corrosion resistance by modifying the metal surface.

These measures are essential to extend the useful life of carbon steel in applications exposed to conditions that promote corrosion.

What are the disadvantages of Carbon Steel?

Carbon steel, despite its many advantages such as durability, versatility and cost-benefit, also has some disadvantages that may limit its applicability in certain contexts. Here are the main disadvantages of carbon steel:

- Susceptibility to Corrosion : As mentioned earlier, carbon steel is prone to corrosion when exposed to oxygen and moisture. This can lead to durability issues and the need for frequent maintenance or replacement, especially in humid or saline environments.

- Low Resistance to Oxidation at High Temperatures : At high temperatures, carbon steel can oxidize more quickly, which compromises its structural integrity. This makes it less ideal for applications that require exposure to high temperatures, such as some parts of furnaces or heat processing equipment.

- Limited Ductility in Some Types : While low carbon steel has good malleability and ductility, high carbon grades are harder and therefore less malleable. This can make forming and working with these steels more challenging and limit their use in applications that require large plastic deformation.

- Poor Resistance to Certain Types of Chemical Corrosion : In addition to common corrosion (rust), carbon steel can be susceptible to other types of chemical corrosion, such as pitting or crevice corrosion, especially in acidic or alkaline environments.

- Need for Surface Treatments for Protection : To overcome some of these limitations, especially corrosion, carbon steel often requires surface treatments such as painting, galvanizing or applying special coatings. These treatments add cost and complexity to the manufacturing process.

- Weight : Compared to some modern materials such as carbon fiber composites or certain reinforced plastics, carbon steel is relatively heavy, which can be a disadvantage in applications where weight is a critical consideration, such as in some automotive and aerospace components.

These disadvantages need to be carefully considered when choosing materials for a specific project to ensure that carbon steel is the most appropriate choice given the operating conditions and performance requirements.

Materials made from Carbon Steel

Carbon steel is one of the most versatile and commonly used materials in industry , given its strength, malleability and cost-effectiveness. It is manufactured in various forms, each suited to specific applications, including sheets, tubes, bars and more. Here are some of the most common carbon steel formats in the industry, with technical details and examples of their applications:

1. Carbon Steel Sheets

- Technical Description : Carbon steel sheets are produced in various thicknesses and can be supplied as hot or cold rolled sheets, depending on the finishing process. Hot rolling is generally used for thicker sheets, while cold rolling provides a smoother surface and more precise dimensional tolerances.

- Applications : Used in shipbuilding, vehicle manufacturing, large metallic structures such as buildings and bridges, and for the manufacture of tanks and pressure vessels due to their ability to withstand large weights and stress conditions.

2. Carbon Steel Pipes

- Technical Description : Carbon steel tubes can be seamless or welded. Seamless tubes are created by extruding steel into the desired shape, while welded tubes are made from steel sheets that are shaped and welded lengthwise.

- Applications : Widely used in piping systems for transporting oil, gas, water, or in civil engineering applications and structures where piping integrity is crucial.

3. Carbon Steel Bars

- Technical Description : Carbon steel bars can be found in a variety of shapes, including round, square, rectangular or hexagonal. They are produced by hot or cold rolling, depending on the required strength and ductility specifications.

- Applications : Used in the manufacture of forged parts, machine shafts, rods, screws and other industrial components that require high mechanical strength and durability.

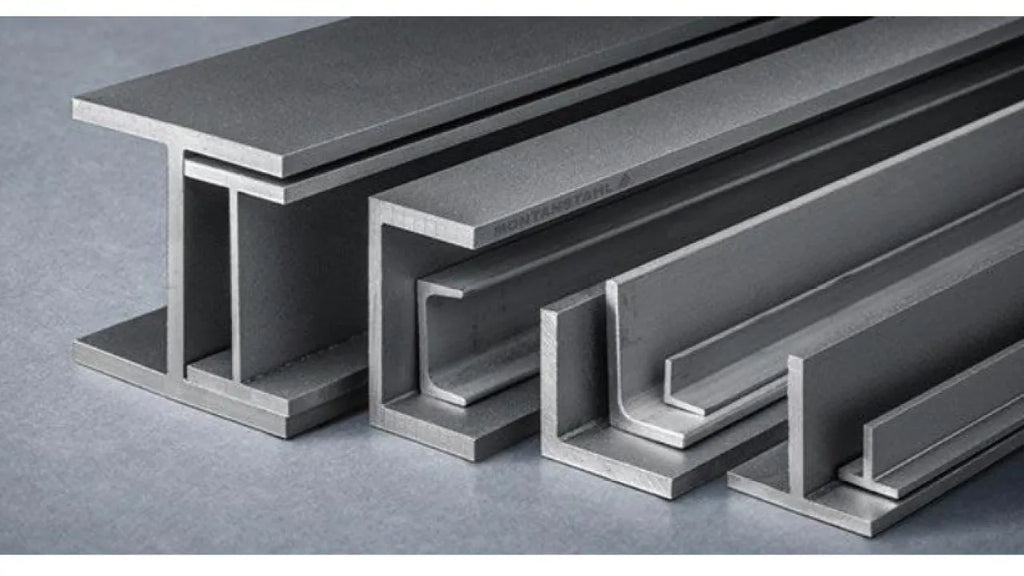

4. Carbon Steel Beams

- Technical Description : Beams, including I-beams (or H-beams) and channel beams, are essential for supporting loads in buildings. They are manufactured primarily through the hot rolling process, which allows the steel to maintain its shape while being formed into long beams.

- Applications : Used as critical structural components in the construction of buildings, bridges and other structures that require heavy load support.

5. Carbon Steel Wire Rod

- Technical Description : Wire rod is a hot-rolled product, with a circular cross-section, used for the production of wires and reinforcing bars.

- Applications : Used to manufacture springs, cables, wires, nails and other products that require high flexibility and tensile strength.

6. Carbon Steel Wires

- Technical Description : Manufactured by drawing wire rod, the wires can have different degrees of resistance, depending on the carbon content and the treatment applied.

- Applications : Used in the manufacture of springs, cables, metal frames and other components that require high resistance to mechanical stress and fatigue.

These are just some of the ways in which carbon steel is used in industry. Each format offers specific properties that meet the needs of very varied applications, highlighting the incredible adaptability and importance of carbon steel in the industrial world.

But let's be honest, there are many more advantages than disadvantages. A true champion of engineering and construction, whose contributions strengthen the foundations of the modern world. Its remarkable properties and adaptability make it worthy of great applause!

Concluding

Carbon steel is one of the most fundamental and versatile alloys used in a wide range of industries due to its distinct properties and adaptability. Characterized by the addition of carbon to iron, this material offers a unique combination of durability, strength and malleability, making it indispensable in everything from construction to high-precision applications in tools and automobiles.

The strength of carbon steel can be adjusted by varying the carbon content and through heat treatment processes, allowing it to meet stringent performance specifications for different applications. From structures that require robustness and flexibility to components that require extreme wear resistance, carbon steel proves to be an efficient and economical choice.

In addition to its functionality, carbon steel also contributes to sustainability. Its ability to be 100% recyclable aligns with modern sustainable production and consumption practices, reducing environmental impact and promoting the reuse of materials in industry.

However, despite its many advantages, carbon steel requires protections against corrosion, especially in harsh environments, which can be achieved through coatings, surface treatments or changes to its composition.

In conclusion, carbon steel continues to be an essential pillar in engineering and manufacturing , offering effective solutions that meet both the technical requirements and efficiency and sustainability objectives of modern industries. Its continuous innovation and development promises to further expand its applications and effectiveness in the near future.