In the current construction scenario, innovation is key to meeting the growing demands for energy efficiency, environmental comfort and sustainability. In this context, the Sandwich Tile emerges as a revolutionary solution, marking a significant advance in roofing technology. This article explores the distinctive characteristics of Sandwich Tile , outlining its impact on the construction industry and how it positions itself as a preferred choice for a wide range of projects.

About Sandwich Tile

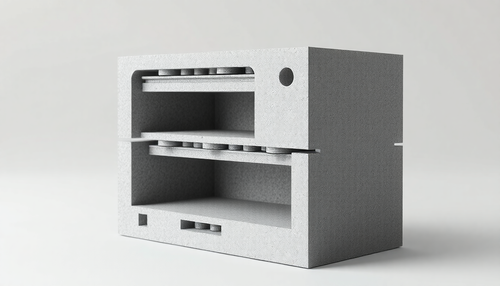

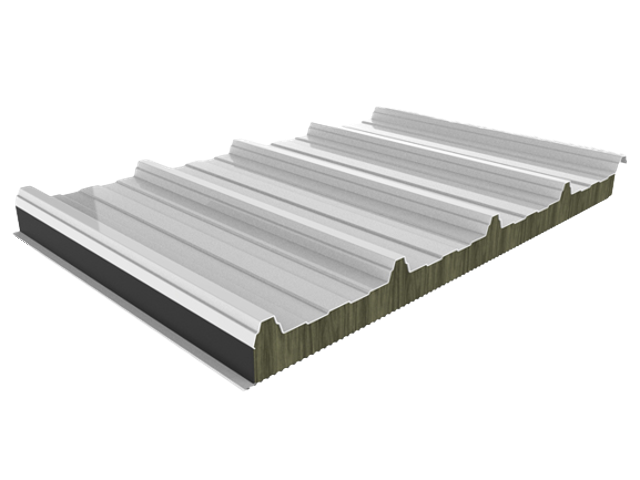

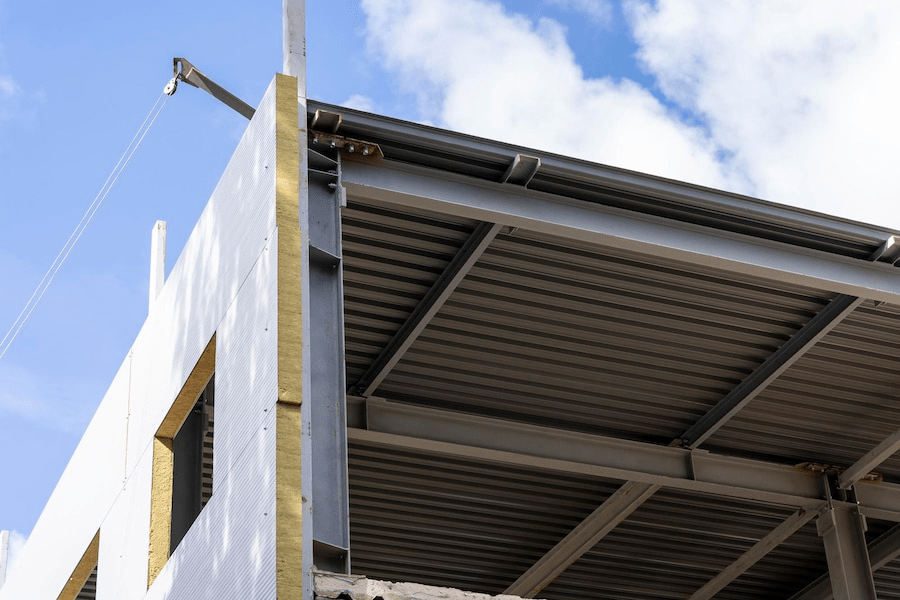

The Sandwich Tile , characterized by its multiple layers, is not just an innovation in terms of material; It’s a redefinition of what we expect from coverage. Combining high-quality materials such as Galvalume steel and galvanized steel with insulating polyurethane (PU) or polyisocyanurate (PIR) foam cores, this tile offers a complete package of benefits. In addition to providing superior thermal and acoustic efficiency, it stands out for its durability and ability to complement the aesthetics of any building.

The integration of these elements gives Telhas Sanduíche a prominent role in projects ranging from commercial and industrial buildings to residences and public facilities. Below, we'll dive into the details of this roofing technology, examining its layers, benefits, and applications, to understand why it's become such a popular and effective choice in modern construction.

What is Sandwich Tile?

The Sandwich Tile, a notable innovation in the field of civil construction, is a roofing system that is distinguished by its multilayer structure. Each layer plays a specific role, combining to provide a roofing solution that is both efficient, durable and aesthetically pleasing. Let's explore in more detail the definition, composition, history, evolution and the varied options of materials and finishes that characterize Sandwich Tiles .

Definition and Composition

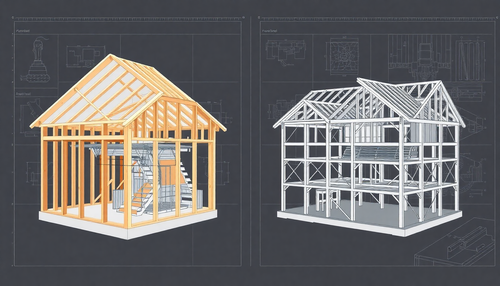

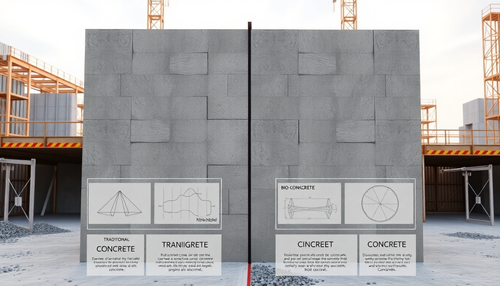

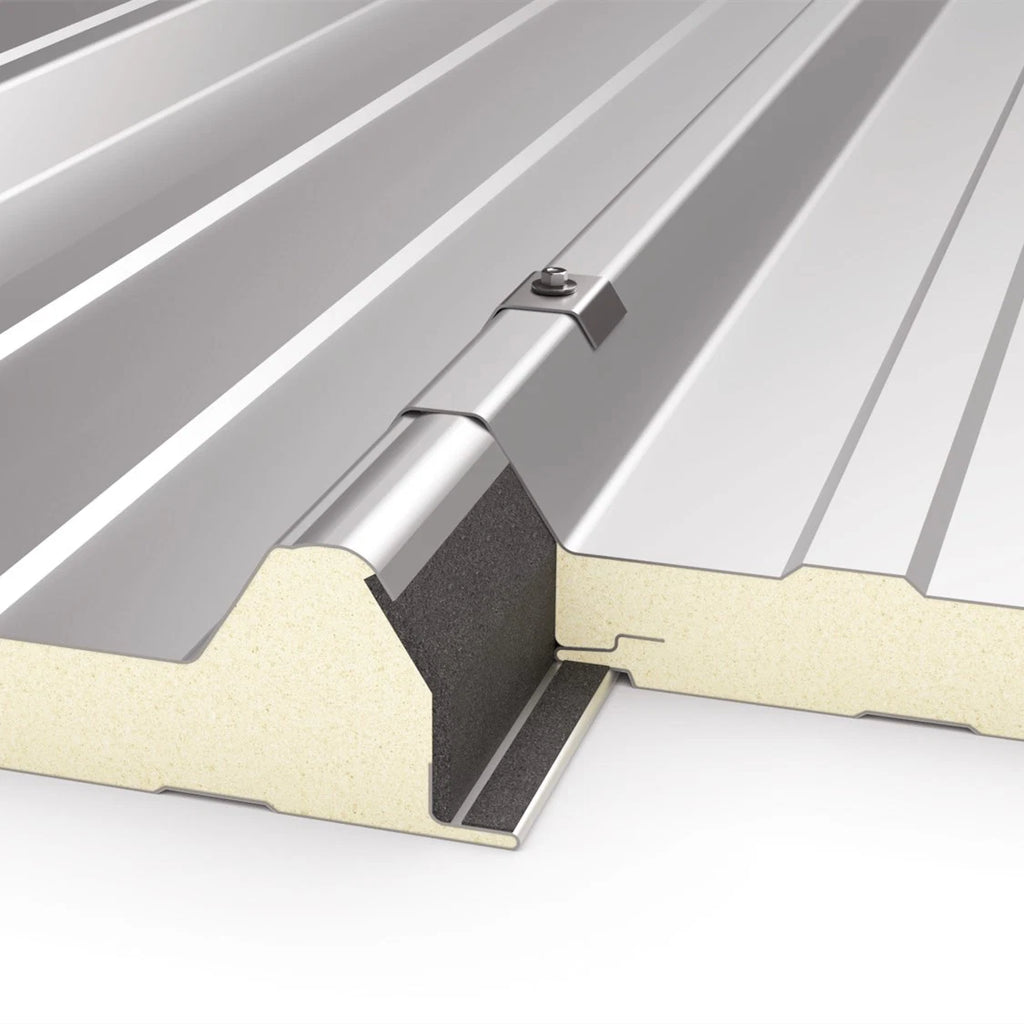

A Sandwich Tile is composed of two outer layers of metallic material, usually Galvalume steel or galvanized steel, which surround an intermediate layer of thermal and acoustic insulation, made of polyurethane (PU) or polyisocyanurate (PIR) foam. This structure not only provides excellent insulation and protection from the elements, but also provides an aesthetically versatile surface that can be adapted to complement any architectural design.

Evolution of Sandwich Tile in the thermal insulation market

The Sandwich Tile concept emerged as a response to the growing demands for construction materials that provide better thermal and acoustic insulation, as well as greater durability and resistance to bad weather. Since their introduction, the technology behind sandwich tiles has evolved, with significant improvements in materials and manufacturing techniques. Initially, they were primarily seen in industrial and commercial construction, but quickly gained popularity in a wide range of applications, including the residential sector.

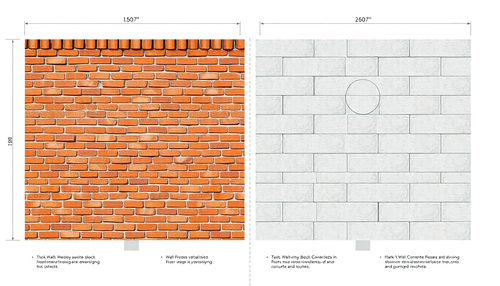

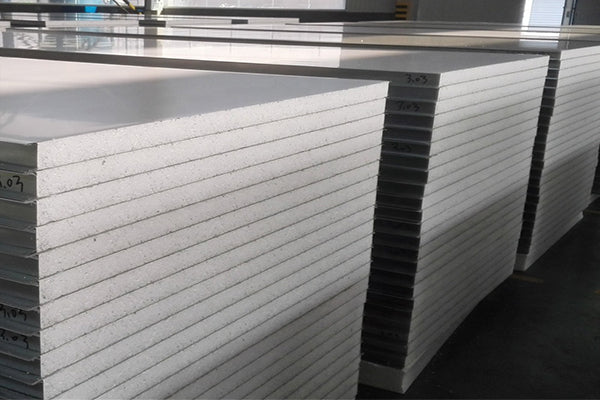

Varieties: Materials and Finishes

Sandwich Tiles are available in a variety of materials and finishes, allowing for a wide range of aesthetic and functional applications. While Galvalume steel and galvanized steel are the most common materials for outer layers, due to their corrosion resistance and durability, finishes can range from electrostatic paints to special coatings that mimic materials such as ceramic and stone.

Additionally, the insulation foam in the core can be chosen based on specific thermal and acoustic insulation requirements, making sandwich tiles a highly customizable solution for construction projects.

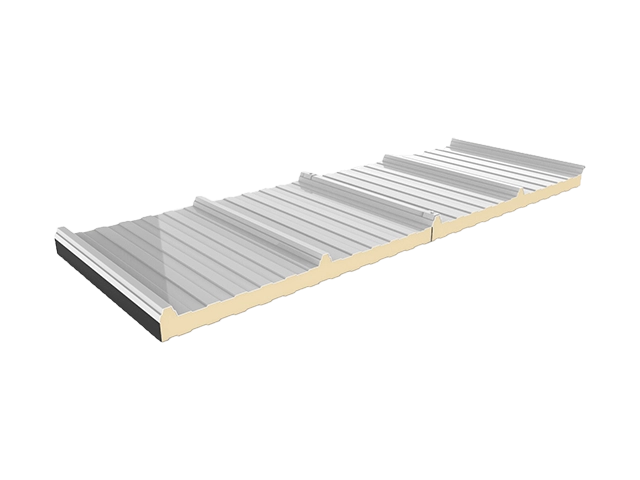

Types of Sandwich Tiles

Sandwich tiles offer a diverse range of shapes and designs, making them suitable for a variety of architectural applications. These shapes and designs vary mainly in terms of profile, finish and outer layer material, each providing specific characteristics for different construction needs. Here are the main shapes and designs of sandwich tiles:

1. Trapezoidal Sandwich Tile

- Profile : Characterized by high trapezoid-shaped ribs.

- Use : Widely used on roofs and facades of industrial and commercial buildings due to its superior structural resistance.

2. Corrugated Sandwich Tile

- Profile : It has a sinuous profile, similar to traditional corrugated tiles.

- Use : Ideal for constructions that require a more classic aesthetic, while maintaining the advantages of thermal and acoustic insulation.

3. Smooth Sandwich Tile (Beaded)

- Profile : Flat surface that can have decorative strips to add an aesthetic element.

- Use : Often used on building facades and in interior wall applications that require a smoother, more modern appearance.

4. Sandwich Tile with Ceramic Tile Finish

- Profile : Combines the efficiency of sandwich tiles with a top layer that imitates the appearance of ceramic tiles.

- Use : Perfect for projects that seek the beauty of traditional tiles with the insulation benefits of a sandwich tile.

5. Sandwich Tile with Metallic Finish

- Profile : Uses metals such as aluminum or stainless steel for the outer layer, offering a glossy or matte finish.

- Use : Used in projects that seek a modern and industrial look, often on facades or prominent roofs.

6. Curved Sandwich Tile

- Profile : Tiles manufactured or curved on site to adapt to arched structures.

- Use : Ideal for buildings with curved architectural designs, such as hangars, sports arenas or innovative commercial buildings.

7. Sandwich Tile for Deck Roofing

- Profile : Designed to act as a working platform during the construction phase, and can be used as the structural base for additional roof systems.

- Use : Commonly used in large commercial or industrial projects where installation efficiency is crucial.

8. Soundproof Sandwich Tile

- Profile : Incorporates specific sound absorption materials to improve acoustic insulation.

- Use : Used in buildings located in noisy environments or where silence is required, such as schools, hospitals and conference centers.

Each type of sandwich tile is designed to meet specific insulation, strength and aesthetic requirements, allowing architects and builders to choose the ideal solution for each specific project. Choosing the appropriate type depends on the application, local climate, aesthetic needs and the project's sustainability goals.

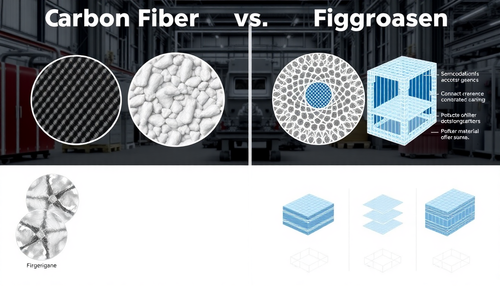

Composition and Technology

Sandwich Tile's innovation and effectiveness derive from its ingenious composition of three distinct layers, combining advanced material technologies to provide superior insulation, durability and aesthetic flexibility. Let's take a closer look at each layer, highlighting the material options and their advantages.

Outer layer: Galvalume Steel and Galvanized Steel

The outer layer of Sandwich Tiles can be manufactured from either Galvalume steel or Galvanized Steel, offering builders and architects flexibility according to the specific needs of the project.

- Galvalume Steel : This aluminum-zinc coated steel alloy is highly resistant to corrosion and is chosen for its longevity and ability to withstand harsh environmental conditions. Its surface reflects solar radiation, contributing to the thermal efficiency of the building.

- Galvanized Steel : Galvanized steel, coated with a protective layer of zinc, also offers excellent protection against corrosion. Although it is slightly more susceptible to damage from scratches compared to Galvalume, it is an economical and durable option that is widely used in a variety of construction applications.

Intermediate Layer: PIR or PU Foam Insulation

Inside the Sandwich Tile is the intermediate layer of insulation, generally composed of Polyisocyanurate (PIR) or Polyurethane (PU) foam. These foams are chosen for their exceptional insulating properties, both thermal and acoustic, which help maintain stable internal temperatures and reduce noise, promoting comfortable and energy-efficient indoor environments.

Insulating Core Material

- Polyurethane (PU) : Provides excellent thermal insulation and is very light. It is one of the most common types of insulation used in sandwich tiles, balancing cost, performance and weight.

- Polyisocyanurate (PIR) : Similar to PU, but with greater fire resistance and better thermal performance. It is ideal for applications that require a higher fire resistance rating.

- Rock Wool : Offers excellent thermal and acoustic insulation properties, in addition to being non-combustible, which provides even better fire resistance. Ideal for places that require sound insulation or are subject to fire risks.

Inner Layer: Painted steel for aesthetics and protection

The inner layer, facing the interior of the building, is made of painted steel. This layer not only serves as an additional barrier against moisture and other indoor elements, but also provides aesthetic opportunities. With a variety of colors and finishes available, painted steel allows Sandwich Tile to seamlessly integrate into the interior design, contributing to the overall appearance of the building.

The multi-layer structure of the Sandwich Tile , using Galvalume steel or galvanized steel combined with high-quality insulation and aesthetic finishes in painted steel, illustrates the harmony between functionality and design. This combination not only meets the structural and insulation needs of modern construction projects, but also opens up new possibilities for architectural expression.

Advantages of Sandwich Tile

Sandwich Tile stands out in the construction materials market for a series of benefits it brings to projects of all types and scales. Its innovative features offer solutions to both practical and environmental challenges in construction.

Thermal Insulation and Energy Efficiency

Thanks to its intermediate layer of insulation, whether made of Polyisocyanurate (PIR) or Polyurethane (PU), Sandwich Tile provides an effective barrier against heat transfer. This superior thermal insulation reduces the need for artificial air conditioning, reducing energy consumption and promoting a more comfortable internal environment.

Acoustic Resistance

The insulation foam used in Sandwich Tile also offers excellent sound absorption properties, significantly reducing the transmission of external noise into buildings. This feature is particularly beneficial in densely populated urban areas or in industrial applications where noise control is a priority.

Durability and fire resistance

Manufactured with Galvalume or galvanized steel, the outer layers of the Sandwich Tile provide robust protection against corrosion, increasing the longevity of the roof. Furthermore, the materials used in the insulating core are chosen for their fire resistance, contributing to the overall safety of the construction.

Lightness and ease of installation

Despite their durability and robustness, Sandwich Tiles are surprisingly light , making transport and installation easier. This lightness reduces the load on supporting structures, allowing for bolder architectural designs and saving installation time and costs.

Sustainability and environmental impact

The use of Sandwich Tiles contributes to sustainable construction in several ways. In addition to improving the energy efficiency of buildings, the materials used are often recyclable, minimizing the environmental impact. This approach aligns with growing demands for building materials that support sustainability and carbon reduction goals.

The advantages offered by Telha Sanduíche reflect a balance between technological innovation and environmental responsibility, making it a preferred choice for projects that aim for efficiency, durability and sustainability. This roofing system not only meets the current needs of the construction industry, but also anticipates the future requirements of a constantly evolving industry.

Applications and Versatility

The Sandwich Tile demonstrates impressive adaptability , meeting the needs of different types of construction. This section explores how it is applied in residential, industrial and commercial contexts, as well as in projects with specific requirements, such as agricultural, logistics and institutional buildings.

Residential: Comfort and economy

In residential constructions, Sandwich Tile is valued for the thermal and acoustic comfort it provides, contributing significantly to a more pleasant and peaceful domestic environment. The energy efficiency resulting from its excellent insulation capacity reduces the need for artificial air conditioning, which translates into savings on residents' electricity bills. Furthermore, the variety of finishes available allows it to harmonize with any architectural style, offering versatile aesthetic solutions.

Industrial and Commercial: Efficiency and functionality

In the industrial and commercial sector, Sandwich Tile is chosen for its durability and resistance , essential for protecting assets and production processes. Its quick and easy installation makes it easy to complete projects in a reduced time, a critical factor for businesses that need to minimize disruptions during renovations or new construction. The ability to maintain stable environmental conditions regardless of external weather fluctuations ensures operational efficiency and protects weather-sensitive goods.

Specialized: Agricultural, Logistics and Institutional

The Sandwich Tile also finds specialized applications in agricultural, logistics and institutional constructions . In agricultural environments, it helps create ideal conditions for storing products or housing animals, while in logistics facilities, it guarantees the integrity of stored goods by maintaining a constant temperature. For institutional buildings, such as schools and hospitals, it provides a silent and comfortable environment, essential for the well-being and productivity of users. In each of these applications, Sandwich Tile proves to be a reliable and efficient solution, adaptable to the specific needs of the project.

Through these applications, it is clear that Sandwich Tile is not just a functional building material; It is a strategic choice that meets performance, aesthetics and sustainability criteria. Its versatility makes it an ideal solution for a wide range of projects, promoting not only efficiency and savings, but also contributing to more sustainable and environmentally responsible constructions.

Installation and Maintenance

Proper installation and regular maintenance are crucial to maximizing the lifespan and performance of Sandwich Tiles . Below is a basic installation guide and maintenance tips, along with important safety considerations.

Step-by-step installation guide

- Area Preparation : Make sure the installation area is clean and free of debris. The support structure must be level and ready to receive the tiles.

- Checking Materials : Before installation, check that all parts are intact and meet project specifications.

- Positioning and Fixing : Start installation at the edge of the roof, aligning the first sandwich tile precisely. Use fasteners suitable for the type of support structure, ensuring that each tile is securely attached.

- Overlapping : Tiles must be overlapped according to the manufacturer's instructions to ensure watertightness. Correct overlap is crucial to prevent leaks.

- Sealing : Apply sealants to joints and edges as needed to reinforce waterproofing.

- Finishing : Check the alignment and fixation of all tiles after installation. Install finishes, such as gutters and flashing, to complete the roofing system.

Maintenance Tips for Longevity

- Regular Inspections : Perform periodic inspections to identify and correct problems such as misalignment, damage or signs of wear.

- Cleaning : Keep tiles free of leaves, debris and other materials that can trap water or promote corrosion.

- Immediate Repairs : When you detect minor damage or leaks, make the necessary repairs immediately to avoid major problems.

Security Considerations

- Personal Protective Equipment (PPE) : Always wear appropriate PPE, including helmets, gloves and seat belts.

- Beware of Heights : Take extra precautions when working at heights by using anchoring systems and stable platforms.

- Tools and Equipment : Use appropriate tools and equipment for the installation, ensuring that they are in good working condition.

- Technical Knowledge : Installation must be carried out by qualified professionals who understand the technical specifications of Sandwich Tiles and best safety practices.

By following these guidelines for installation and maintenance, Sandwich Tiles will provide durable and efficient coverage, ensuring the safety and comfort of building occupants.

Facing Climate Extremes

Challenge : Sandwich Tiles must withstand a wide range of weather conditions, from extreme heat and prolonged sun exposure to torrential rain and heavy snow loads.

Solutions :

- Weather Resistant Materials : Use materials specially treated to resist corrosion, UV fading and deterioration under adverse weather conditions.

- Reinforced Insulation : For regions of high temperature or extreme cold, increasing the thickness of the insulating layer can provide better thermal control.

- Proper Design : Ensure the roof design incorporates features such as appropriate slope and effective drainage systems to handle heavy precipitation or snow accumulation.

Solutions to common installation problems

Challenge : Installation issues such as inadequate fixing, incorrect alignment or insufficient sealing can compromise the integrity and effectiveness of the cover.

Solutions :

- Professional Training : Train installation teams with specific training on the best practices and correct techniques for installing Sandwich Tiles.

- Specific Tools : Use tools and equipment designed for installing these tiles, ensuring the precision and effectiveness of the process.

- Quality Check and Control : Implement a rigorous quality check and control process during and after installation to ensure all aspects are up to required standards.

Technological innovations and improvements

Challenge : Stay ahead in the construction industry by incorporating the latest innovations and technological improvements to optimize the functionality and performance of Sandwich Tiles.

Solutions :

- Advanced Materials : Research and adopt cutting-edge materials for the external and insulating layers, improving energy efficiency, fire resistance and durability.

- Intelligent Design : Develop profiles and fitting systems that facilitate installation, improve watertightness and increase structural resistance.

- Sustainability : Focus on sustainable production, using recyclable materials and processes that minimize environmental impact, while maintaining superior performance.

By paying attention to these issues and seeking effective solutions and continuous innovations, Sandwich Tiles will continue to be a preferred choice in construction projects, offering an unbeatable combination of performance, aesthetics and sustainability.

Case studies

Sandwich Tiles have proven to be a versatile and effective solution in a variety of applications. Here, we highlight three case studies that exemplify its value in residential, commercial and industrial projects.

Residential: Transforming homes with energy efficiency

Case : A residence located in a region with a hot and humid climate was looking for a solution to reduce energy consumption with air conditioning, without compromising internal comfort.

Solution : The installation of Sandwich Tiles with a high-density PIR insulation layer was chosen to replace the traditional roof. The solution offered not only a modern and attractive aesthetic, but also superior thermal performance, reflecting solar heat and keeping the interior cool.

Result : After installation, the home saw a significant reduction in air conditioning usage, resulting in substantial savings on energy bills. Furthermore, internal thermal comfort has been notably improved, with more stable internal temperatures, even on the hottest days.

Commercial: Large structures with complex requirements

Case : A new shopping center was looking for a roofing solution that combined energy efficiency, modern aesthetics and quick installation, due to the tight deadline for opening.

Solution : Sandwich Tiles were chosen due to their ease of installation and excellent thermal insulation. The ability to customize finishes allowed for perfect integration with the center's architectural design.

Result : Construction was completed on schedule, with the roof meeting all energy efficiency and aesthetic requirements. The shopping center not only stood out visually, but also provided a comfortable shopping environment for visitors regardless of the external weather conditions.

Industrial: Controlled environments for optimized production

Case : A factory needed a covering solution that maintained controlled environmental conditions to protect temperature- and humidity-sensitive production processes.

Solution : Sandwich Tiles with specialized insulation were installed, creating a highly efficient building envelope. This choice ensured the maintenance of stable internal temperatures and protection against humidity, crucial for the integrity of the production process.

Result : The solution provided precise environmental control, resulting in improvements in product quality and production efficiency. Additionally, the factory benefited from significant reductions in operating costs due to the reduced need for air conditioning.

These case studies demonstrate the flexibility and effectiveness of Sandwich Tiles in meeting and exceeding expectations in projects of different scales and requirements. Their ability to provide customized, high-performance solutions makes them a valuable choice for any construction project.

Technical Standards

The relevant technical standards for the manufacture, specification and use of tiles, including Sandwich Tiles , are established by the Brazilian Association of Technical Standards (ABNT). These standards guarantee that products meet the quality, safety and performance requirements necessary for their application in construction. Some of the relevant technical standards for Sandwich Tiles in Brazil include:

- ABNT NBR 15575 : This series of standards establishes the performance requirements for residential buildings, addressing thermal, acoustic comfort and durability, which are directly related to the characteristics of Sandwich Tiles.

- ABNT NBR 16453 : Deals with procedures for determining the fire resistance of construction elements, including coverings such as Sandwich Tiles.

- ABNT NBR 14514 : This standard provides guidance on the handling and installation of steel roofing tiles, covering aspects that may be applicable to Sandwich Tiles, especially those with metallic outer layers.

It is important to consult the most recent versions of these standards for detailed, up-to-date information. Additionally, for specific projects or applications that require particular performance criteria, there may be other additional standards and regulations to consider. Construction professionals, such as architects and engineers, can offer additional guidance on which standards are applicable in each case, ensuring that projects meet all current legal and technical requirements.

Concluding

Sandwich Tiles are a milestone in construction technology , bringing efficiency, robustness and versatility to face modern challenges in construction. Combining Galvalume or galvanized steel and effective insulation, they offer excellence in thermal and acoustic insulation, durability and fire resistance, in addition to adapting to different designs. Essential for sustainable construction, they reduce energy consumption and environmental impact, harmonizing aesthetics with performance and sustainability.

The ease of installation and adaptability expand their future use, with potential for innovations that promote greener and more advanced constructions, highlighting them as promising solutions for the evolution of civil construction.