BS 8110 Material Properties

BS 8110 Part 01 1997 contains diagrams that can be used when building from scratch. Stress-strain relationships for concrete, reinforcement, and prestressing steel are given in the code.

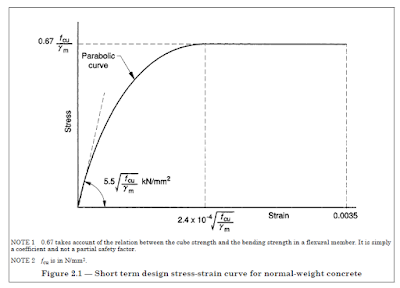

The following figure shows the stress-strain relationship of concrete.

According to the diagram above, the maximum load that concrete can bear is 0.0035 and the maximum stress depends on the quality of the concrete.

Furthermore, the maximum stresses of concrete depend on the material's safety factor, which is 1.5.

Therefore, the maximum stress of concrete is 0.45 fcu.

The codes contain equations for flexural and shear design considering the values given in the figure above. Unless we design according to basic principles, we don't need to worry much about the above values.

Simplified stresses and deformations in concrete can be seen in the following figure.

The figure above is used to find concrete stresses and deformations when we design according to basic principles.

The following figure shows the stress-strain relationship of reinforcing steel.

According to the figure above, the stress-strain relationship is simplified to a level that is easy to understand.

The maximum stress of the reinforcing steel is given by the yield strength divided by the material safety factor, which is 1.05 according to BS 8110 (click here for more information).

The elongation at the point where the steel reaches the above stress is called the yield strain and is 0.002.

The following figure shows the stress-strain relationship for prestressing steel

Figure 2.3 of BS 8110 is used in the design of prestressed concrete beams.

Especially when we design beams with different shapes, we start from basic construction principles. In these situations we need to use the curve above for construction.

Furthermore, the strength of the material can be increased when the strain rate is very high.

For example, an element subjected to an explosive pressure load deforms in a very short period of time. For more information, see the article Improving structural strength .