Increasing the temperature of concrete beyond a certain level causes serious problems. Therefore, it is very important to limit the temperature when pouring concrete. Failure to control the increase in concrete temperature will result in Concrete wear Before it hardens, delayed formation of ettringite, etc.

Reason for increasing concrete temperature

The hydration process generates heat and this is released into the environment as thermal energy. Heat is created by the reaction of water and cement. This is a complex reaction that needs to be discussed in the context of how different materials react. C 3 S E C 3 A are the cement components that have the greatest influence on the heat of hydration. They generate greater heat compared to other components.

Maximum temperature allowed for concreting

The maximum allowable increase in concrete temperature cannot be defined with an exact value. It depends on the type of concrete and its composition. However, there are general standards to limit the temperature of concrete.

The American Concrete Institute also offers some guidance on temperature fluctuations.

According to general building regulations, it is set at 70 degrees Celsius . However, this value may vary depending on the construction project. The main objective of limiting temperature rise in concrete is to prevent cracking of immature concrete and prevent delayed ettringite formation.

The exact temperature at which retarded ettringites are formed cannot be specified, but the temperature rise is limited to 70 degrees Celsius.

Some guidelines have increased this limit beyond the value indicated above based on the amount of materials added, such as fly ash. Furthermore, the addition of materials such as fly ash as filler reduces the heat of hydration and consequently reduces the temperature rise of the concrete.

According to general standards, the addition of fly ash is up to 35% . Furthermore, the following limitations are also taken into consideration in construction projects to control temperature rise.

- The usual practice is to limit the temperature difference between the outer surface of the concrete and the 20 Celsius core. However, for some projects, this value is left at 25 degrees Celsius, taking into account the size and type of concrete to be used.

- Furthermore, the temperature gradient must not exceed 25 Celsius per linear meter. If construction is done keeping the above points in mind, early cracking in concrete can be minimized.

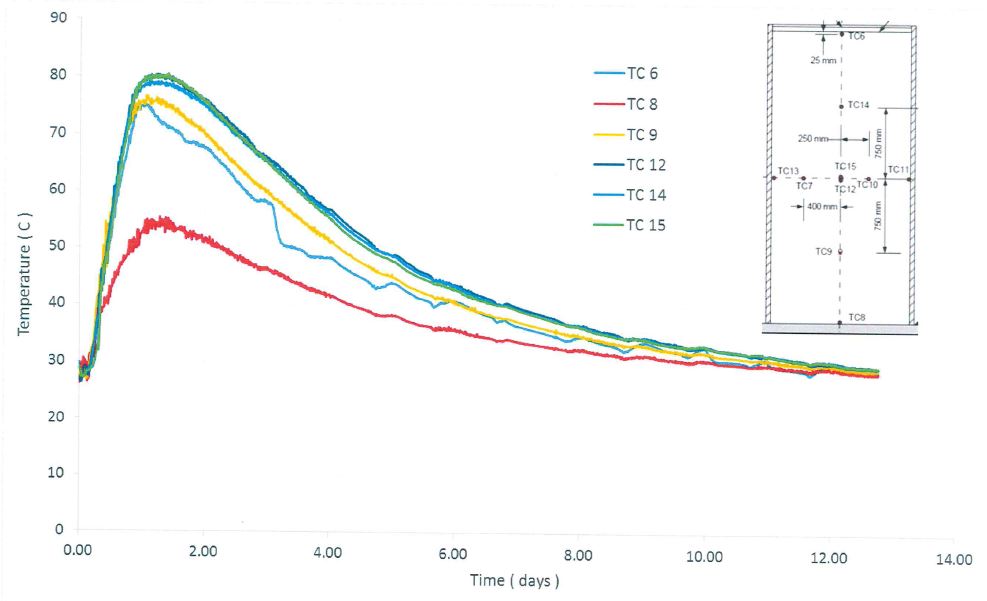

Additionally, core and surface temperature increases will be monitored to verify that they are within limits through a simulation test that accurately represents on-site conditions.

Why should we limit the temperature of concrete

The most important question. Reason for temperature limitation. In fact, temperature is an indicator of the heat generated in the hydration process. The lower the heat, the lower the risk.

The idea behind the concrete's temperature limit is to prevent cracking at different stages of its life. Improves the durability of concrete. This is one of the Factors that affect the durability of concrete. If the temperature is not controlled, the following problems may occur.

- Crack formation in raw concrete

- Internal cracks due to increased core temperature

- Internal/surface cracks due to higher temperature gradients

- Delayed ettringite formation and subsequent cracking in concrete

How to limit the temperature when concreting

There are several methods that can be used to control the temperature rise in concrete. The individual methods are explained below.

Local temperature reduction

The temperature at which the concrete is placed directly influences the increase in the temperature of the concrete as it begins to rise from this temperature. Therefore, it is necessary to take the necessary measures when mixing concrete. In accordance with BS 5328 Part 1 Installation temperature should be 30 degrees Celsius Unless otherwise stated.

The following actions could be taken:

- Unit pre-cooling

- Use ice/cold water to mix concrete

- Remove water from pipes buried underground.

- Do not store material in direct sunlight. To maintain the temperature of the unit, continuous spraying with water can be carried out.

- Store cement in a low temperature environment. If cement is stored in silos, it is advisable to cover them. Additionally, silos can be painted with reflective paint to minimize heat absorption. In addition, cement can be well ventilated when stored in the warehouse to avoid temperature rise.

Controlling temperature rise in immature concrete

- Reduces the temperature increase in the hydration process due to the higher cement content. Substitute materials such as fly ash can be used to control cement content and reduce temperature.

- Choose the aggregate grain size carefully. The use of coarse aggregates depending on the concrete mix can help reduce the temperature rise of the concrete.

- It is better to pour the concrete in several batches than to pour it all at once.

- Effective hardening of concrete. The article Concrete Hardening Methods could be forwarded.

- Use tubes embedded in the concrete to absorb the heat generated by the hydration process.

- Provides insulation to control temperature gradient

- Use low temperature cement. Fast-setting cement should be avoided to reduce heat generation due to high hydration rate.

- Use of additives. Retarders can delay the hydration process so that heat development does not occur suddenly.

- Concreting must be carried out at night.

- Protect concrete from direct sunlight.

- Mixing and placing concrete should be done as early as possible. The longer the transport takes, the more heat is generated by friction.