The reinforcement rib is the component that creates the connection between the concrete and the reinforcement. Therefore, it is very important to study the surface geometry of reinforcing steel.

When reinforcement is placed in concrete, it acts as a composite material. Reinforcement makes its contribution when there is a good connection between the concrete and the reinforcement.

The stress in concrete and steel arises mainly from the ribs of the reinforcing bars. The surface geometry of reinforcing bars is the main factor contributing to the development of bond stress.

The article Rated anchor bond stress More information on calculating bond stress according to BS 8110 can be found here.

We focus on the geometry of reinforcing ribs specified in BS 4449:2005.

The surface geometry of reinforcing bars is explained below.

- Rib dimensions

- Number of ribs

- Arrangement of transverse and longitudinal ribs.

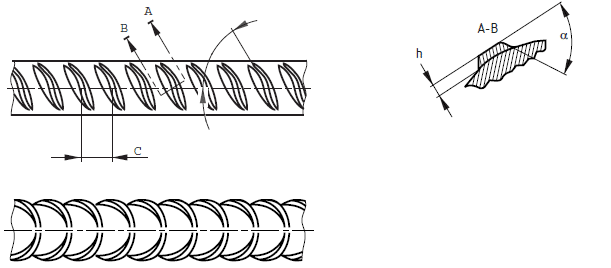

To determine the geometry of the rib, the following information or parameters/dimensions are taken into account.

- Rib height

- Spacing between ribs

- Rib inclination

The following figure shows the typical arrangement of reinforcing ribs.

BS 4449:2005 specified the allowable range for rib height, rib spacing and pitch.

| Rib height, h | Spacing between ribs, c | Rib inclination, β |

| 0.03d to 0.15d | 0.4d to 1.2d | 35 0 to 75 0 |

Where d is the nominal diameter of the rod.

The characteristic relative area of the ribs must correspond to the following table (p=0.95).

The method for calculating the relative area of ribs must comply with BS EN ISO 15630-1:2002.

| Nominal bar size, d/mm | Relative rib area |

| d ≤ 6 | 0.035 |

| 6 < d ≤ 12 | 0.040 |

| T > 12 | 0.056 |

Transverse ribs

The following parameters are taken into consideration for the geometry of reinforcing ribs in accordance with BS 4449.

- The transverse ribs should be approximately half-moon shaped and flow smoothly into the bar.

- The transverse ribs must protrude at least 75% of the bar's circumference. The nominal diameter must be taken into account in this calculation.

- The slope α of the transverse rib flank must be greater than or equal to 45° and the transition from the rib to the core must be reduced.

This criterion is identical to the code.

Longitudinal ribs

The height of longitudinal ribs should not exceed 0.1d when added to reinforcing bars.