Air-entrained concrete is a type of concrete designed to improve its durability and workability in extreme temperature environments. It is an effective solution for civil engineering projects such as pavements, bridges and dams as it helps protect against freeze-thaw cycles and chloride-related corrosion. This blog post explores the benefits of air-entraining concrete and provides civil engineers with the technical information needed to effectively implement it in their projects.

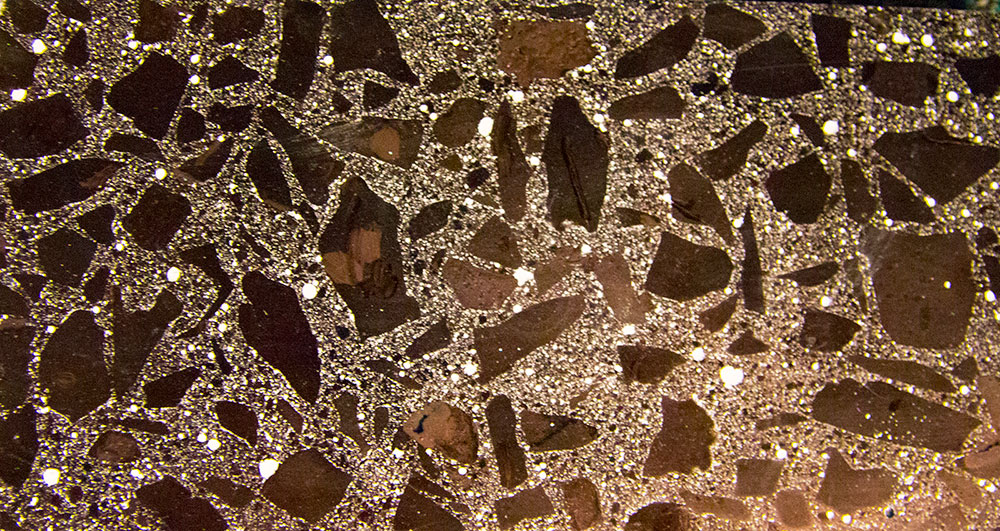

- Under careful technical supervision, these types of concrete are manufactured using air-entraining Portland cement or by adding air-entraining agents during mixing of the concrete. The amount of trapped air varies depending on the specific circumstances, but is typically between 4% and 7% of the concrete volume.

- The strength of concrete decreases due to the formation of air inlets. The direct reduction in strength is typically 5-6% per 1% of air entry, while the improved workability of air-entry concrete can partially offset this effect.

- To protect concrete from internal and external damage caused by salt deposits in cold environments, the air retention method is often used.

Important Facts About Air-Entraining Concrete

Some of the following factors are influenced by air pockets in concrete

- Concrete Workability – Overall Improved

- Concrete strength – generally reduces

- Permeability – Increases

- Shelf life for freezing and thawing – improvement

- Thaw resistance – improvement

Furthermore, some of the main benefits of air-entrained (non-trapped air) concrete are as follows.

- Light bleeding

- Improving the sulfur capacity of concrete

- Reduce concrete shrinkage and the formation of surface cracks due to shrinkage

The first advantage of air-entrained concrete is its greater durability. The tiny air bubbles in concrete mixes act like little shock absorbers and help protect the concrete from the stresses of freeze-thaw cycles and thermal expansion. This means that air-entrained concrete is less likely to crack and crumble over time, making it a more durable and long-lasting building material.

Another advantage of air-entrained concrete is its better workability. The air bubbles present in the concrete mix help make the concrete smoother and easier to work with. This is particularly beneficial in cold climates when traditional concrete can become quite hard and difficult to work with. The better workability of air-entrained concrete makes it a more versatile construction material that can be used in a variety of applications.

Civil engineers must be aware of the benefits when designing projects that require a strong and durable construction material. When used correctly, air-entrained concrete can help improve the durability and workability of the finished project.

What are the disadvantages of air-entraining concrete?

One of the main disadvantages is the higher cost. Its production is more expensive than traditional concrete due to the additional cost of the air-entraining agent. These higher costs can be a significant factor in selecting a building material for a project.

Another disadvantage of air-entrained concrete is its lower strength. The small air bubbles present in the concrete mix act as weak points that can reduce the overall strength of the concrete. This is an important consideration for civil engineers because the strength of concrete is a key factor in the safety of the finished project.

Although air-entraining concrete offers many advantages, its higher cost and lower strength must be taken into consideration when selecting the construction material for a project.