Air-entraining agents have proven to be incredibly useful in achieving the desired workability, strength and durability of concrete mixes used in the construction of engineered structures. As a civil engineer, it is important to understand the properties that these additives can impart to a concrete mix and how to ensure their effective and optimal use. In this blog article, we explore the use of air-entraining agents and the ways they can help achieve the desired results in any construction project.

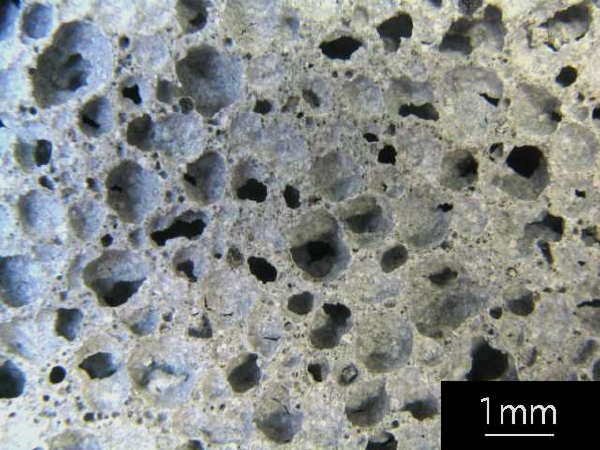

Air-entraining agents are substances added to concrete to create small air bubbles in the mix. This makes the concrete more porous and therefore less dense. The main advantage of using air-entraining agents is that they improve the workability of the concrete and facilitate its placement and work. Additionally, air entrainment can also reduce the water content of concrete, meaning it is less susceptible to shrinkage cracking.

When used correctly, air-entraining agents can help create a concrete mix that is strong, durable, and easy to work with. However, it is important to consider the impact of air ingress on the construction process to ensure the concrete mix is suitable for the specific project.

Influence of air entraining agents

- Improve the workability of concrete

Spaced bubbles in concrete reduce friction between cement particles. This means we can take advantage of the low water content and do without water-reducing additives to achieve high processability.

- Reduce the strength of concrete

Adding air to concrete reduces its strength. According to test results, a 1% increase in the proportion of air in concrete appears to reduce the compressive strength of concrete by approximately 4-6%.

- Improve waterproofing

- Reduces segregation and bleeding

- Improving deposit resistance through de-icing blades

- Improve resistance to cyclic freezing and thawing

Other advantages of air-entraining agents

In addition to the many benefits that air-entraining agents add to the concrete mix, they also have some important effects on the construction process.

First, entraining air reduces the density of concrete, which means it is easier to transport and place. This can be a significant advantage when working on large projects where concrete needs to be moved frequently.

Secondly, air inclusions can also reduce the water content of concrete, reducing the risk of shrinkage cracks. This is an important consideration in any construction project, as shrinkage cracks can potentially weaken the structure.

Finally, air retention can also affect the processability of concrete , making it easier to place and finish.

Although air-entraining agents offer many benefits, it is important to use them correctly to achieve the desired results. One of the most important considerations is the amount of air intake required for the specific mixture. This varies depending on the type of concrete used and the desired properties. Too much air intake can cause the concrete to become very porous and weak, while too little air intake can result in a concrete mix that is difficult to work with.

It is clear that air-entraining agents can significantly influence the properties of concrete. When used correctly, they can help create a mixture that is strong, durable, and easy to work with. However, it is important to consider the impact of air ingress on the construction process to ensure the concrete mix is suitable for the specific project.