Concrete curing is one of the most important factors in concrete construction, as it is associated with properties such as characteristic strength, permeability, durability , etc. Furthermore, curing must be done at the right time, and sufficient curing time is very important to achieve the precise properties of concrete.

Concrete curing serves to prevent evaporation of water from the concrete during curing and to maintain moisture on the concrete surface for hydration reactions.

Furthermore, it is necessary that Temperature gradient i.e. the temperature drop per unit length and the temperature difference between the core and the surface. In general, temperature differences and gradients are around 20-25 degrees Celsius.

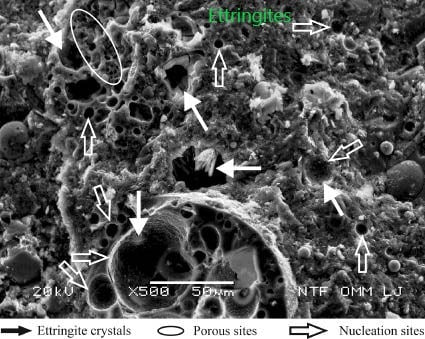

Furthermore, the rise in core temperature must be reduced and an increase above 70 degrees Celsius increases the risk of delayed ettringite formation . This reaction increases the internal volume and as a result cracks appear in the concrete. The core temperature can be reduced by adopting the internal cooling method, which will be explained in the last part of this article.

Therefore, proper curing of concrete is essential for durable and strong concrete.

Methods for Curing Concrete

- Water hardening

- Wet cover

- Formwork hardening

- Membrane hardening

- Plate hardening

- Heat absorption hardening

- Hot mixing process

- Electric curing

- Infrared healing

- Cover with sand or sawdust, earth, etc.

- Natural post-treatment (exposed concrete)

1. Hardening with water

Water is applied to prevent the concrete surface from drying out. Typically this method is used when the concrete is thinner.

In construction, this process can be used, for example, to treat floor slabs.

There are two methods of applying water to concrete.

- Concrete dam

- Use sprinklers to distribute water continuously

Formation of puddles in concrete

With this method, the concrete surface is continuously moistened without allowing the concrete surface to dry out. A curb stone thrown around the slab often helps moisten the area in question.

This method is very useful in dry environments because it does not require continuous watering. All flat surfaces such as roads, slabs, sidewalks, etc. can be easily cured using this method.

Use of sprinklers

It is essential to avoid drying out the concrete surface due to evaporation. To ensure sufficient curing, continuous, constant and even spraying of water is required.

For this, sprinklers are used at a sufficient distance.

As shown in the figure above, the moisture content does not fall below the required level and this is a very simple method as it does not require much effort like manual curing.

2. Wet icing

Moist curing is a method of maintaining the moisture content of a surface through the application of materials such as jute. The use of Gunnery Bae is also common.

This coating must be applied to the concrete surface when it has hardened enough to serve as a covering. Furthermore, the concrete surface must not dry out for any reason.

The methods described under the heading “Water hardening” can only be used to harden horizontal surfaces. Vertical surfaces on concrete pillars, walls, etc. can be cured using this method as shown in the following figure.

3. Formwork hardening

Formwork is the most effective hardening agent in construction. This method is particularly used for thick concrete with high hydration temperature.

Furthermore, there are no costs because the costs are already covered by the formwork. The only problem is that the formwork will have to be maintained a little longer than usual.

If there is a risk of cracks forming in large concrete components due to irregularities in the concrete surface, post-treatment of the formwork offers greater safety.

If heat transfer in thick concrete becomes a problem, formwork hardening is used as an alternative. According to the heat, maximum temperature, temperature gradient and temperature difference, the thickness of the formwork can be determined.

Typically Model testing is performed on thicker concrete types to monitor temperature fluctuations. The test is carried out before the concrete work begins.

Depending on the test result, the formwork material, its thickness, the concrete installation temperature, measures to reduce the heat of hydration, etc. are carried out. Generally, the test is carried out under the above conditions and checks whether they are acceptable.

During the hardening of the pillars, the formwork must be used for longer than normal. Therefore, additional costs may be incurred for the project.

4. Membrane hardening

A membrane is formed on the surface of the concrete to prevent moisture from the concrete from evaporating.

Liquid molding material is sprayed onto the surface of the concrete, solidifies and forms a membrane. These materials can be applied with a brush or roller. There are two types of membranes.

- Water based

- Oil base

Water-based curing membranes are more popular than oil-based because they can be washed with water after the curing period and removing oil-based membranes requires additional effort. Removal of oil-based membranes requires acid etching, sandblasting or chipping.

5. Curing the panels

There are two types of plates used for healing.

- Polyethylene Film

- plastic film

- Healing blankets

Both types of films are typically used to cure flat surfaces. Polyethylene sheets are used to cover concrete slabs and pillars. The film can be placed on the board immediately after hardening.

Protective areas can also be created using polyethylene film in addition to applying it to the concrete. This allows the concrete to dry naturally. For special occasions with less evaporation and concrete that is not as structurally important, this method can be used.

Plastic sheets can also be used to cover concrete. These films are used to cover flat surfaces. It is a waterproof and lightweight material. Furthermore, it is easy to handle.

Additionally, curing mats are used to protect the newly laid concrete. They have the same effect as another type of foil. There is no evaporation of moisture from the concrete surface.

6. Heat absorption hardening – water cooling in pipes

There are tubes embedded in the concrete that absorb heat. Water circulates in concrete and absorbs heat from the concrete.

This method is particularly suitable for thick concrete and in construction with higher quality concrete. Reduces core temperature.

However, these methods must be used with great caution, as the sudden change in temperature can cause cracks in the concrete.

Continuous water temperature monitoring provides information about internal temperature. Based on these observations, the flow rate can be adjusted.

7. Hot mixing method

Increasing the temperature of the concrete aims to improve the strength of the concrete.

Increasing the temperature of concrete to 32 0 C could increase strength by 10-20%.

As concrete reaches strength early, this method can be used in situations where initial strength is required. Furthermore, the formwork can be removed early because strength is acquired early.

There are several methods that can be used to increase the temperature of concrete

- Increase unit temperature by heating

- Heat the water

- Inject steam into the concrete mix

This method requires the use of special formwork, and formwork must also be used. This method is not normally used and can be used on special occasions.

8. Electrical healing

There are three electrical hardening methods.

- Electric current flows through the freshly laid concrete between two external fixed electrodes. Alternating current must be conducted through the concrete.

- A high current with low voltage flows through the amplification network.

- Large electric blankets are used to heat the plate surfaces.

9. Infrared Healing

This is not a very common method and is not used often.

The formwork is heated or hot water is circulated through the concrete.

10. Cover with sawdust, sand or earth

This method can be used particularly for thick concrete with a small surface area.

Concrete surfaces on pile caps, slab foundations, etc. they can be covered with sand, sawdust and earth.

A membrane is placed over the concrete and sand is spread over it.

Controls the variation of the concrete surface.

11. Natural Healing

Concrete can harden naturally without anything being covered.

Concrete can cure naturally in environments with very little evaporation and no high heat to harm the concrete.

This is particularly possible with structural elements that are not of great importance. However, structurally important elements cannot be repaired using this method.

The higher the evaporation rate, the greater the risk of cracks in the concrete. Furthermore, temporal fluctuations in surface temperature lead to cracks in the concrete.

Furthermore, the moisture required for the hydration process is not sufficient. This leads to a reduction in the strength of the concrete and can be considered as a factor that affects the durability of the concrete .